Metalworking division

Electrical & Automation Division

Integrated projects

Metalworking division

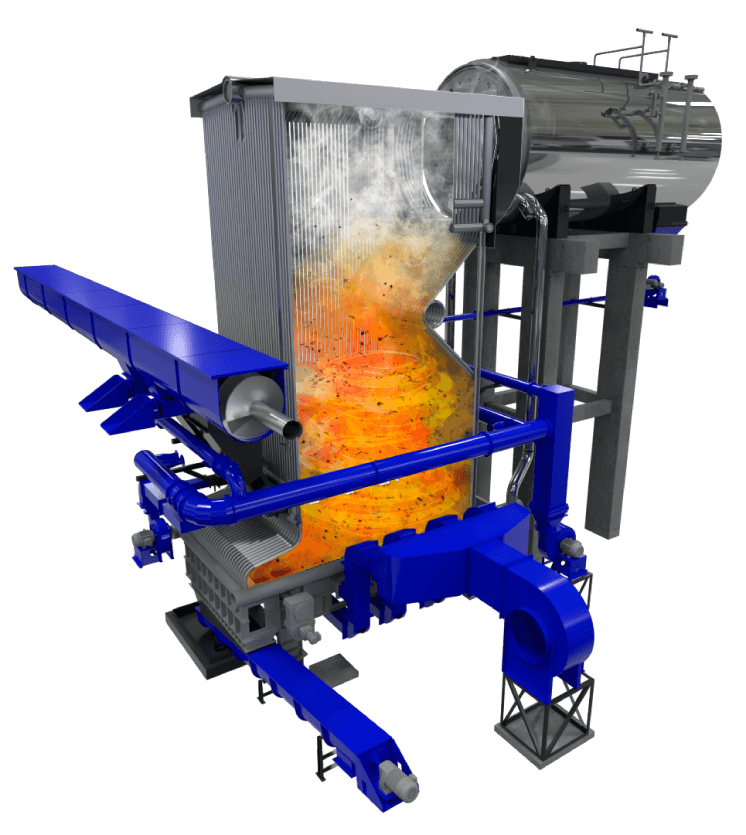

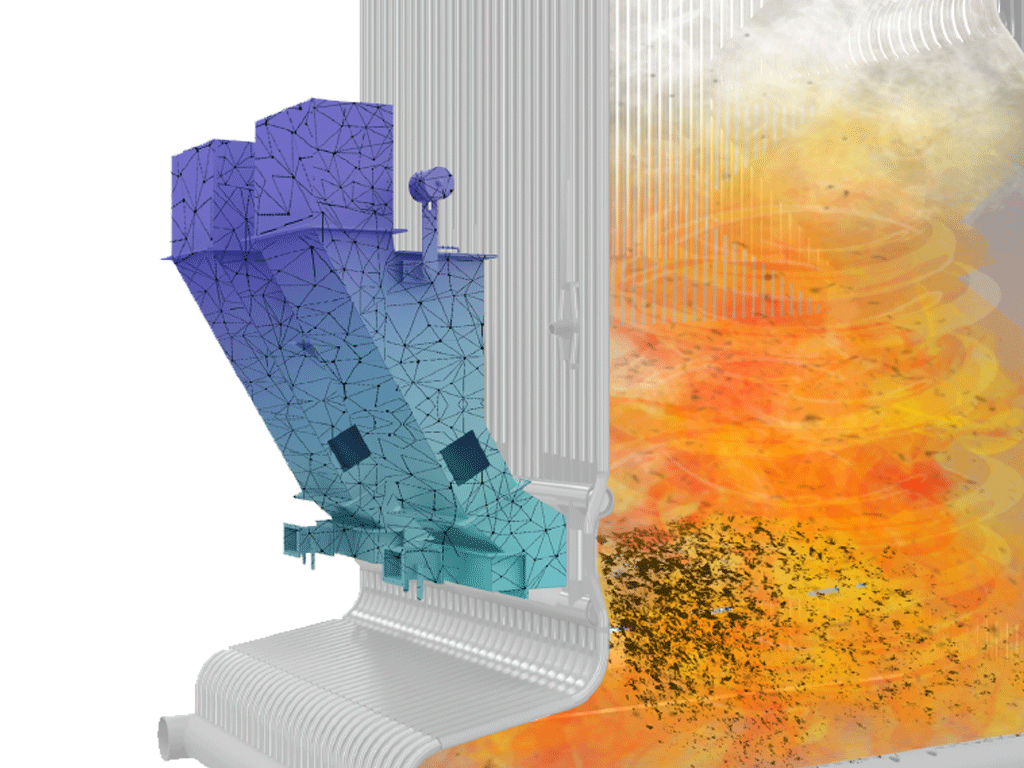

Boilers

Process Equipment for Oil & Gas

Solutions for the Energy Sector

Electrical & Automation Division

Integrated projects