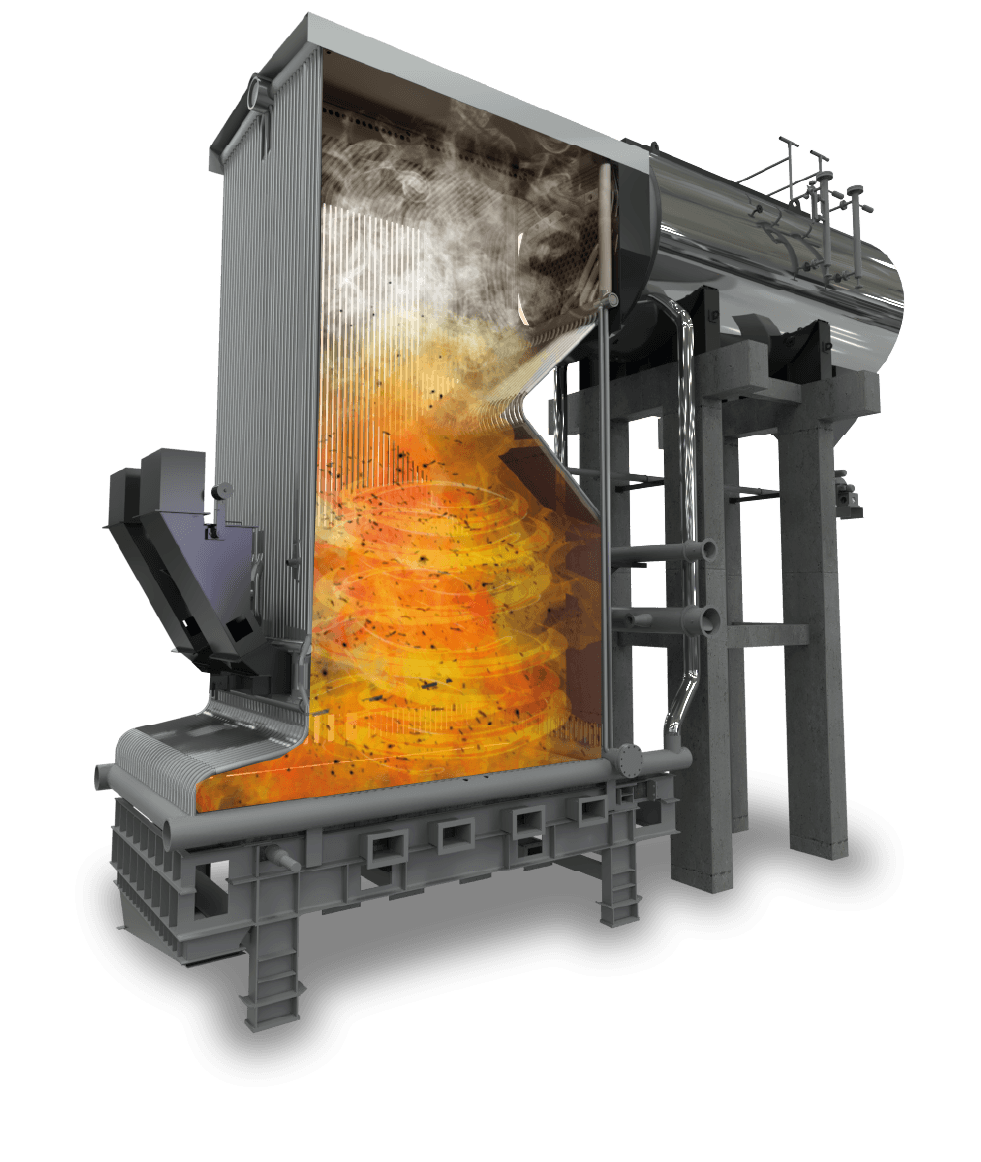

Boilers for biomass

Efficiency and Sustainability in Every Combustion.

Energy Transition

The disproportionate use of fossil fuels is harming the environment. The burning of these fuels contributes to climate change and air pollution. At VR Ingeniería, we offer an eco-friendly solution for generating steam from biomass, supporting the transition to renewable and sustainable energy sources.

CO₂ Reduction

Fewer Harmful Emissions

Renewable Energy.

Biomass Utilization

Environmental Commitment

Eco-friendly Solutions

Environmental Commitment

Eco-friendly Solutions

Benefits of biomass boilers

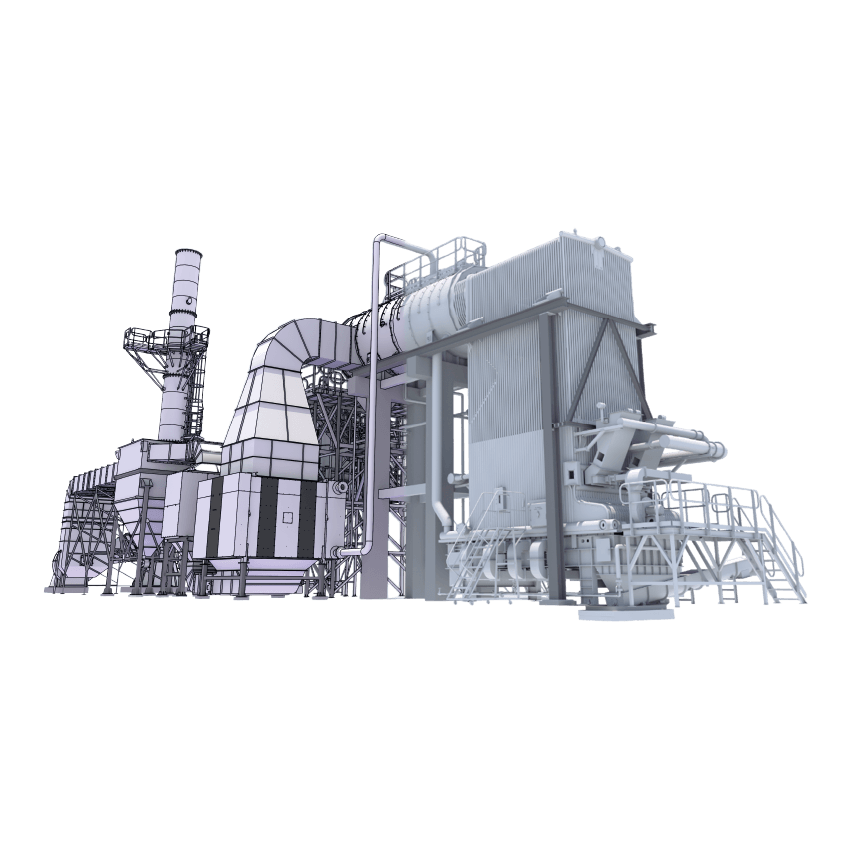

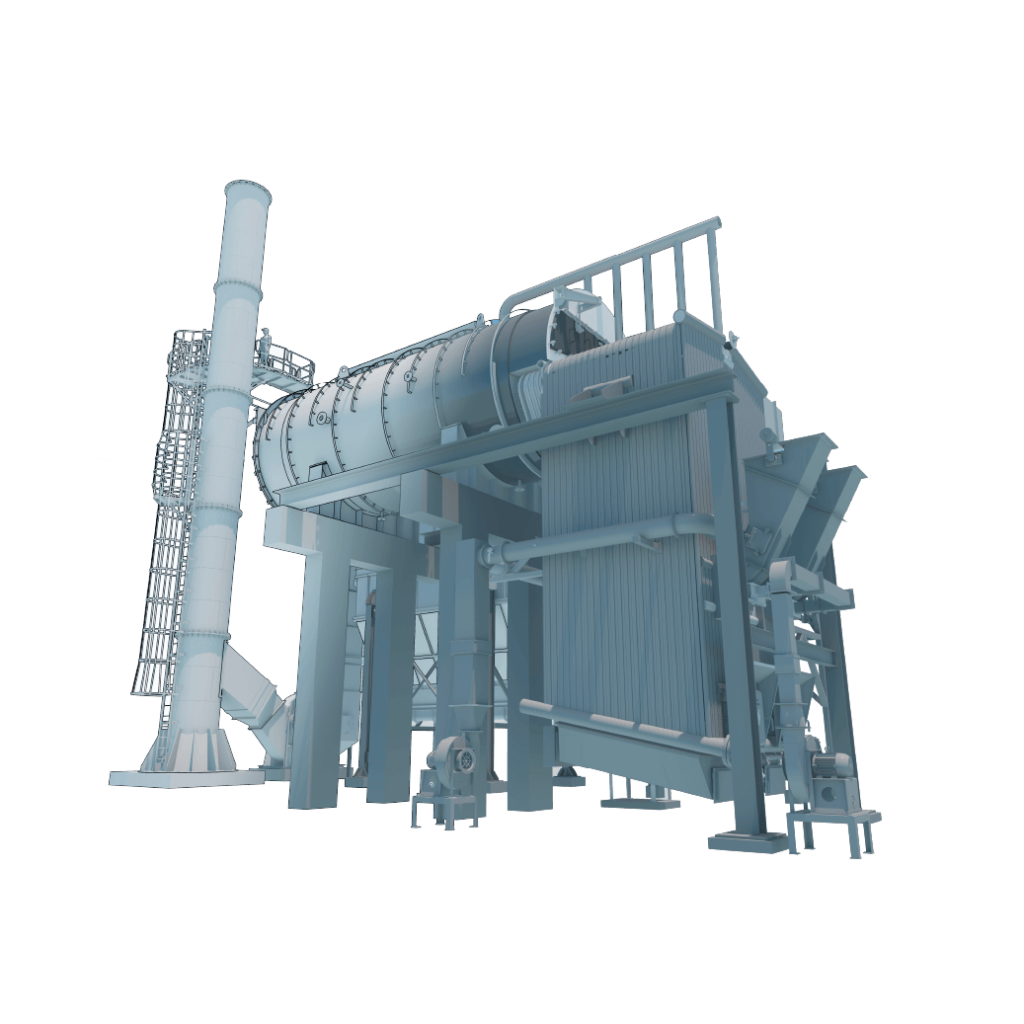

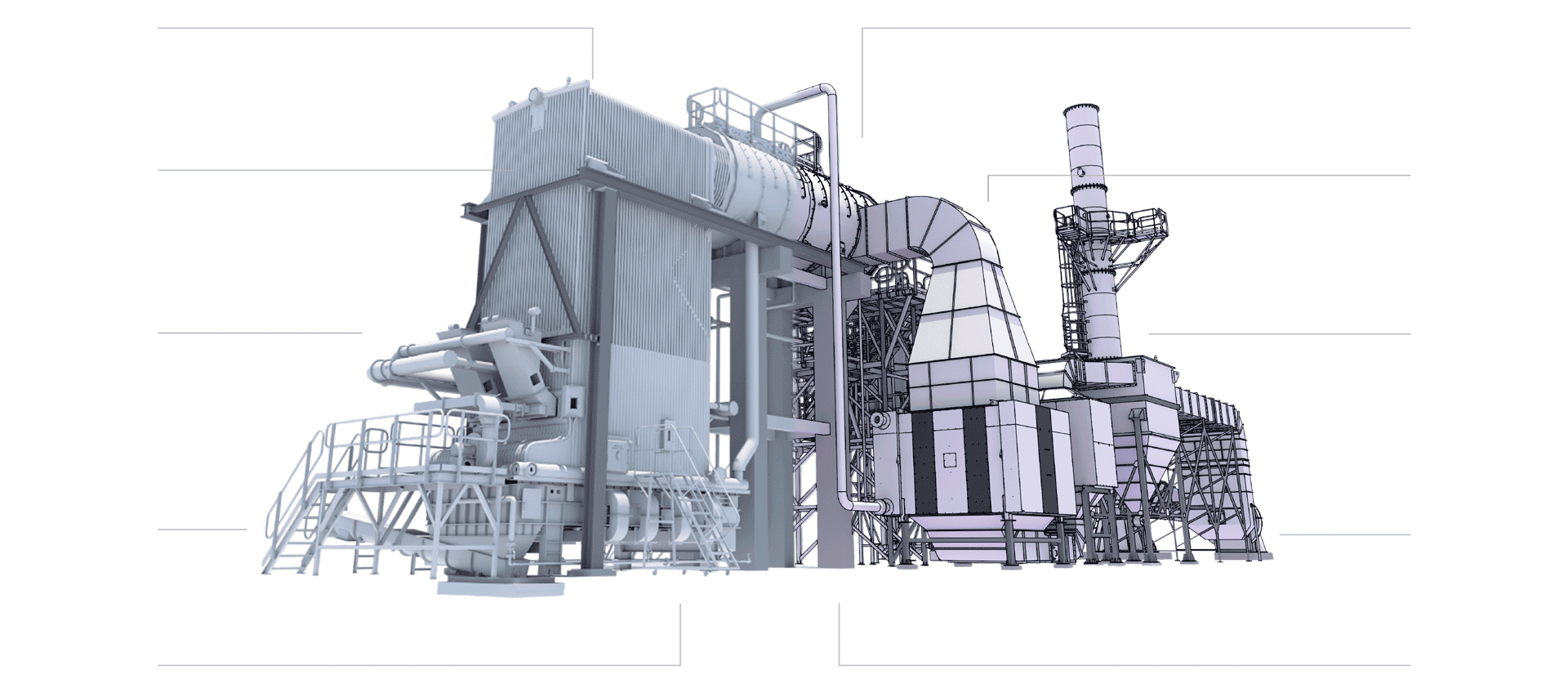

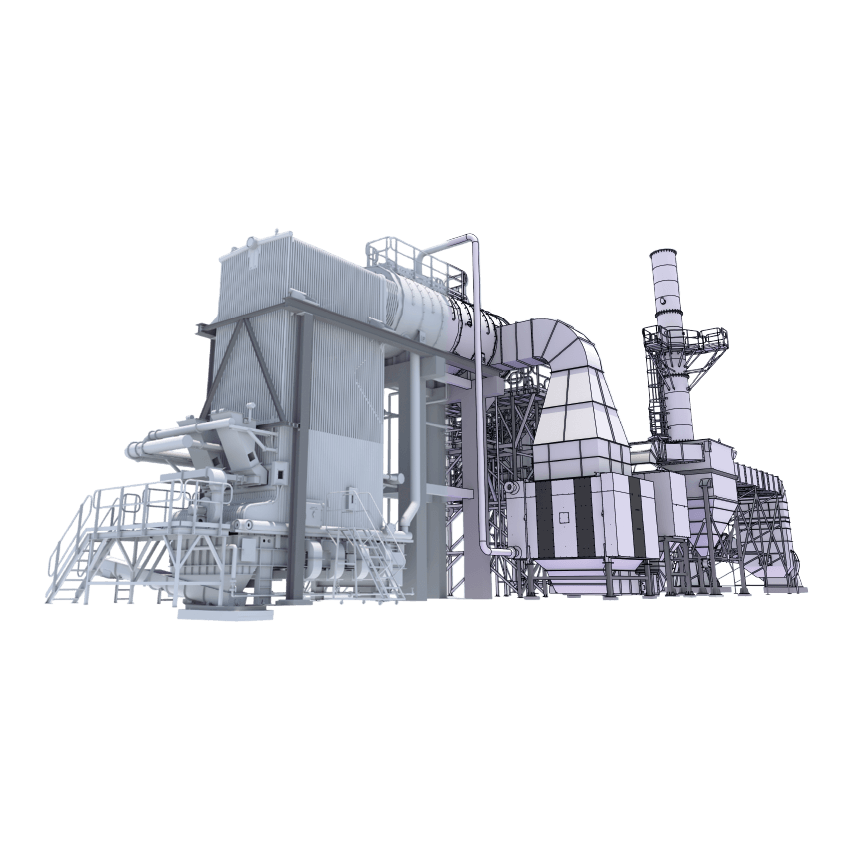

At VR Ingeniería, we have nearly 40 years of passion and commitment in the analysis, design, manufacturing, and improvement of environmentally responsible combustion systems for various biomass types. Thanks to our VR Boiler CAD tool, we improve our response time and provide customized solutions addressing specific factors such as moisture content, calorific value, and chemical composition.

Energy Optimization System that Maximizes Combustion and Heat Transfer Efficiency

Robust and Reliable Design that Ensures Very High Machine Availability

Optimized design to increase operational availability, extending the time between interventions, with high-reliability auxiliary equipment and control systems from recognized brands, supported locally.

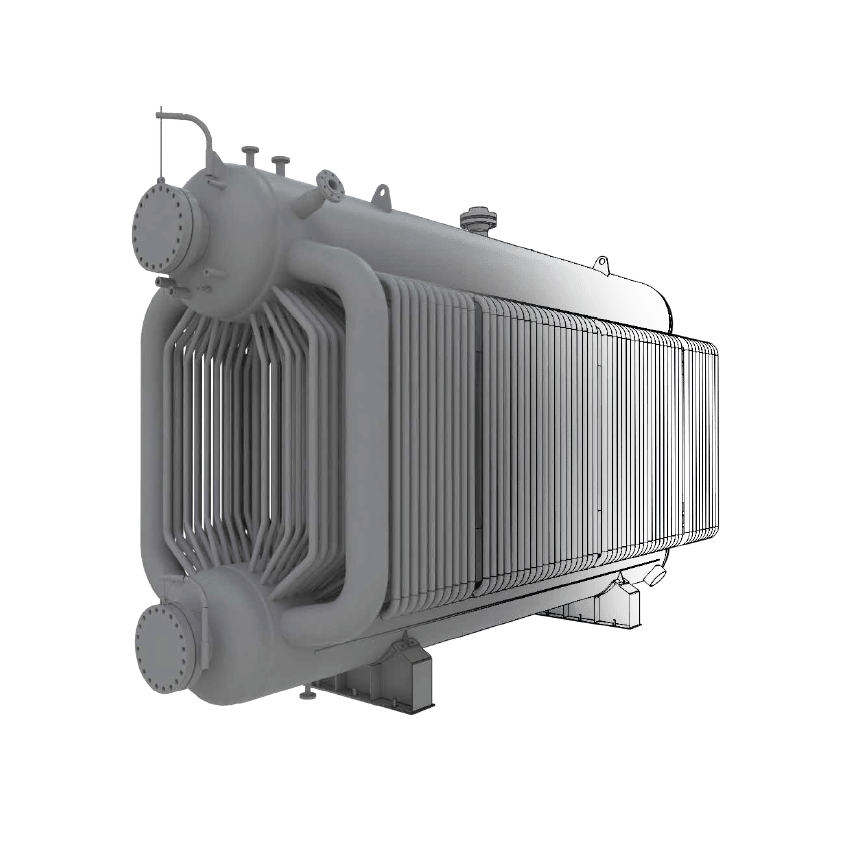

Boiler

Minimal human intervention.

Package-type Fire-tube Heat Recovery Unit or Tube Bank, Transportable and Easy to Install, Reducing Costs and Risks of Assembly

Clean, Complete Combustion and Optimal Flue Gas Temperature in the Furnace, Minimizing Fouling in the Convective Zones

Boilers Designed, Manufactured, and Stamped According to ASME Code Sec I

National Board Registration

Fully automated control system with state-of-the-art equipment, making operation, monitoring, and control an easy and pleasant experience.

Fully automated control system with state-of-the-art equipment, making operation, monitoring, and control an easy and pleasant experience. Fully automated control system with state-of-the-art equipment, making operation, monitoring, and control an easy and pleasant experience. Fully automated control system with state-of-the-art equipment, making operation, monitoring, and control an easy and pleasant experience. Fully automated control system with state-of-the-art equipment, making operation, monitoring, and control an easy and pleasant experience.

Advanced control logic with frequency variation ensures the lowest energy consumption in pumps and fans.

Energy Optimization System that Maximizes Combustion and Heat Transfer Efficiency

Robust and Reliable Design that Ensures Very High Machine Availability

Optimized Design to Increase Operational Availability by Extending Intervals Between Interventions, with High-Reliability Auxiliary and Control Equipment from Recognized Brands with Local Support

Minimal Human Intervention

Package-type Fire-tube Heat Recovery Unit or Tube Bank, Transportable and Easy to Install, Reducing Costs and Risks of Assembly

Clean, Complete Combustion and Optimal Flue Gas Temperature in the Furnace, Minimizing Fouling in the Convective Zones

Boilers Designed, Manufactured, and Stamped According to ASME Code Sec I

National Board Registration

Fully Automatic Control System with State-of-the-Art Equipment Making Operation, Monitoring, and Control an Easy and Enjoyable Experience

Unbeatable combustion system and auxiliary equipment that guarantee compliance with environmental standards.

Unbeatable combustion system and auxiliary equipment that guarantee compliance with environmental standards.

Energy optimization system.

To optimize combustion in boilers, we develop the most efficient system by collaborating with experts and using advanced techniques. We redesign each component to ensure maximum energy efficiency in biomass boilers.

Below, we present the components designed in this process.

01. | Fiber injection system

02. | Traveling grate

03. | Combustion chamber

04. |Secondary air

05. |Optimization equipment

06. |Emission control systems

Biomasses from African Palm Oil Extraction

At VR Ingeniería, we use biomass generated from African palm oil extraction to meet all the energy needs of industrial processes, eliminating additional CO₂ emissions. Our solution maximizes energy efficiency and reduces the carbon footprint, reaffirming our commitment to sustainability.

Among the reusable biomasses from this process are:

Other Types of Biomass:

Pellets

Coffee Husks

Sugarcane Bagasse

Rice Husk

Contact us

¡Contact us! We are ready to help you.