Heat Exchangers

Solutions for Industrial Process Optimization

We specialize in heat exchangers.

Our commitment goes beyond the quality of our products. We are deeply invested in the economic and social development of our communities. We believe that businesses play a key role in job creation and in training the next generation of specialists. By investing in our team and sustainable technologies, we are contributing to building a stronger economy and a more equitable society.

Manufacturing Capacity

Nearly of 40 years of experience

Nearly 40 years in the industry guarantee our expertise and knowledge in the production of heat exchangers.

High Quality Standards

Producción con los más altos estándares de calidad para asegurar la fiabilidad y durabilidad de nuestros productos.

Technology

We combine technology and technical expertise with efficient processes to ensure reliability in every product we manufacture.

Extensive Production Capacity

We are equipped with the best technology for precision part manufacturing, ensuring exceptional results.

We design custom equipment

We design custom heat exchangers to meet each client’s specific needs. Our team uses specialized software for mechanical, thermal, and hydraulic calculations. This optimizes the performance, energy efficiency, and durability of our heat exchangers.

We adhere to the most demanding industry standards, and our processes are aligned with international quality and safety standards. This commitment ensures our clients’ trust and contributes to a more sustainable future.

Energy Efficiency:

We design our equipment to maximize heat transfer, which can result in more efficient energy use. This can reduce operating costs and greenhouse gas emissions.

Customization

We have the capability to design and manufacture custom heat exchangers to meet the specific needs of each customer. This can result in products that are better adapted to the plant's operations and can improve its performance.

Versatility

We design for a wide range of temperatures and pressures, making them suitable for various applications.

Quality

All our heat exchangers are subjected to rigorous testing and quality assurance tests to guarantee their performance and durability. Our commitment to quality is unwavering.

Durability

Thanks to precise material selection and a detailed manufacturing process, our heat exchangers are more durable and require less maintenance. This can reduce long-term costs and minimize plant downtime.

Regulatory Compliance

All our products comply with industry regulations and standards, such as the ASME code. This ensures the safety and efficiency of the heat exchangers.

We design our equipment to maximize heat transfer, which can result in more efficient energy use. This can reduce operating costs and greenhouse gas emissions.

We have the capability to design and manufacture custom heat exchangers to meet the specific needs of each customer. This can result in products that are better adapted to the plant’s operations and can improve its performance.

We design for a wide range of temperatures and pressures, making them suitable for various applications.

All our heat exchangers are subjected to rigorous testing and quality assurance tests to guarantee their performance and durability. Our commitment to quality is unwavering.

Thanks to precise material selection and a detailed manufacturing process, our heat exchangers are more durable and require less maintenance. This can reduce long-term costs and minimize plant downtime.

All our products comply with industry regulations and standards, such as the ASME code. This ensures the safety and efficiency of the heat exchangers.

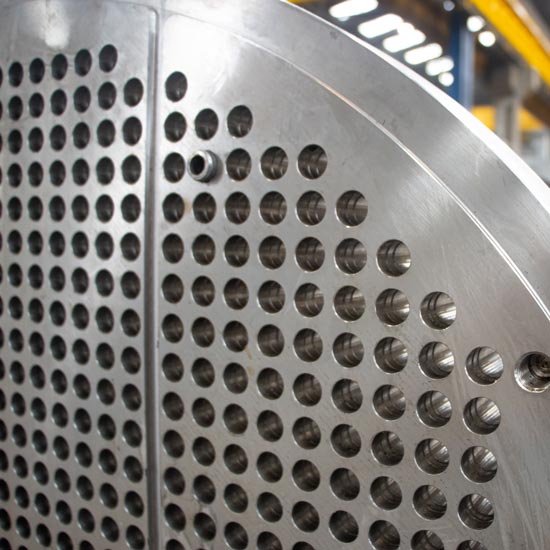

Advanced Manufacturing Processes

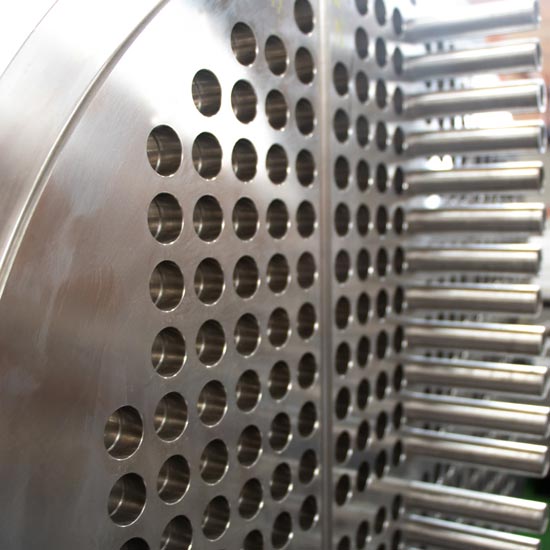

Our company specializes in the manufacturing of heat exchangers for the oil & gas sector, using production processes that ensure high quality, mechanical strength, and reliable thermal performance.

Each phase, from design to delivery, is focused on meeting the most demanding operational requirements, ensuring safe, durable equipment ready for high-pressure and high-temperature environments.

We use advanced welding techniques to ensure the integrity of our heat exchangers. Our trained and qualified welders guarantee joints that withstand the high pressures and temperatures of the operations to which the equipment is subjected.

Our precision machining processes enable us to manufacture components with exact tolerances, ensuring a perfect fit and optimal performance of our heat exchangers.

We use forming techniques to shape the components of our heat exchangers. This allows us to create complex designs that maximize the heat transfer surface area.

All our heat exchangers are rigorously tested to ensure their performance and durability. This includes pressure tests to verify the strength of materials and welds and leak tests to confirm the efficiency of the joints.

Solutions by Industry

Heat exchangers are essential devices in various industries due to their ability to efficiently transfer heat between two or more fluids. At VR Ingeniería, we design and manufacture heat exchangers for the following applications:

Oil and Gas Production

Cooling and condensation of natural gases.

Petrochemical

Temperature control in processes such as polymerization, cracking, or distillation.

Energy generated

Preheating of crude oil and condensation of distillation products.

Refineries

Heat transfer from power generation systems to steam or refrigeration systems.

Transforming Challenges into Opportunities

Success Stories

Explore some of our most notable projects and learn in detail how our solutions have made significant and positive impacts on our clients.

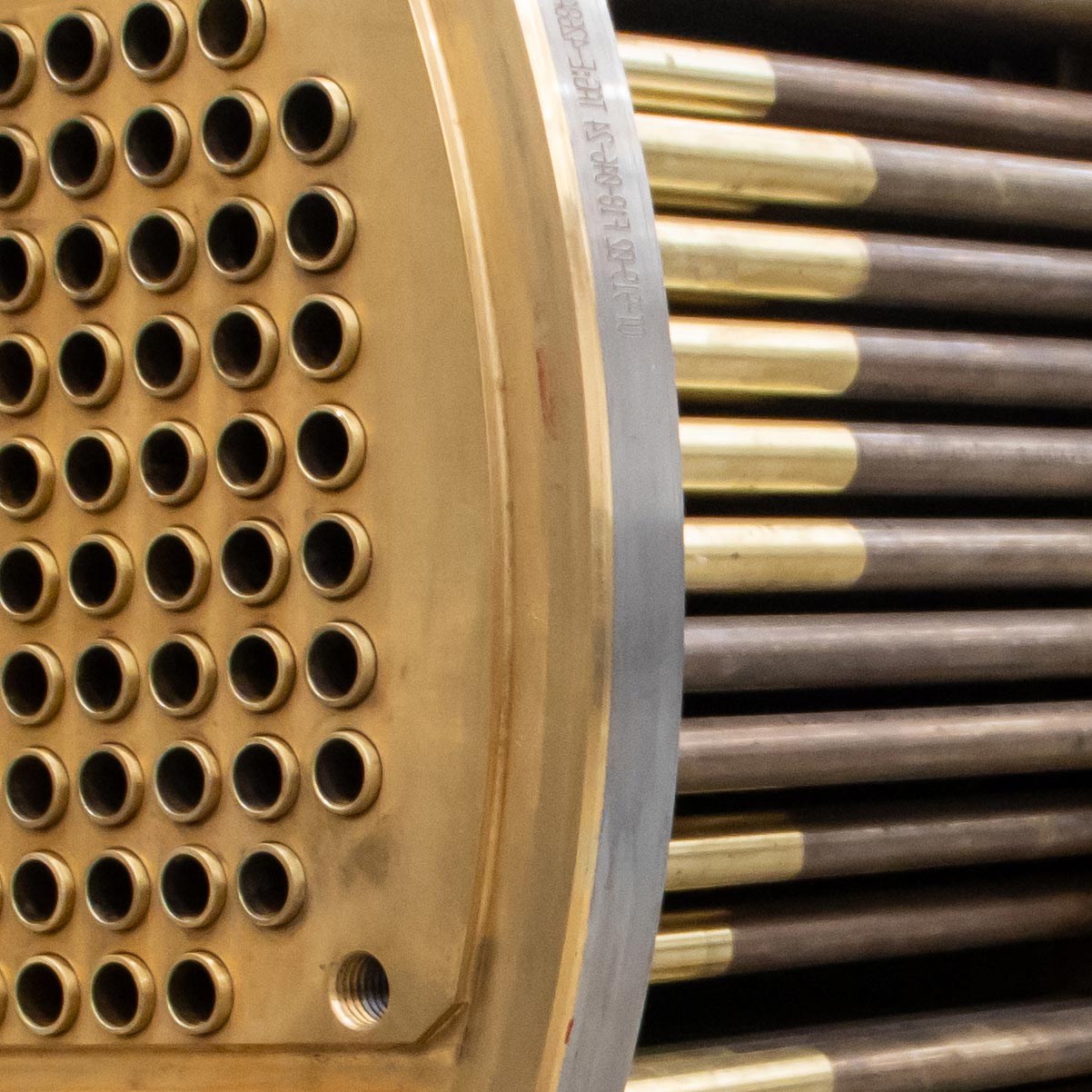

Floating head heat exchanger for H₂S service

Floating head heat exchanger for H₂S service

– Tubes and baffles made of bronze, to enhance heat transfer between fluids.

– Tube sheets manufactured using the cladding process between P1 and P32 materials.

– Tube-to-tube sheet joint by expansion.

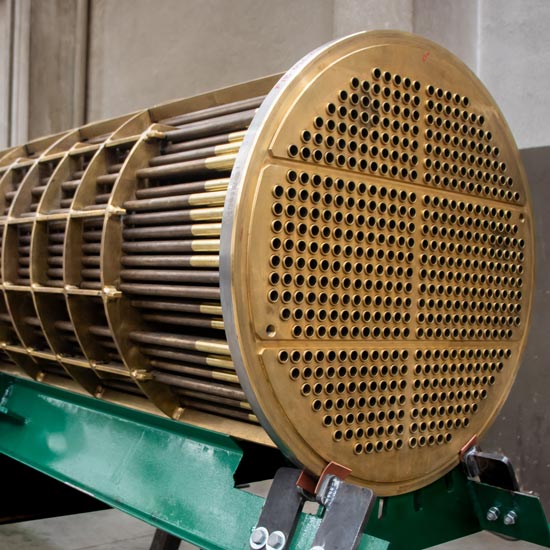

Stacked AES-type heat exchanger

Stacked AES-type heat exchanger

– Manufactured from austenitic stainless steel, resistant to corrosion.

– Tube-to-tube sheet joint by expansion and seal welding.

BEM heat exchanger

BEM heat exchanger

– Tube sheets and tubes manufactured from Duplex stainless steel.

– Shell manufactured from austenitic stainless steel.

– Tube-to-tube sheet joint by expansion and seal welding.

– Suitable for low-temperature operation (-50°C).

BKU shell and tube bundle

BKU shell and tube bundle

– Carbon steel tube sheets with NACE requirement.

– Tube-to-tube sheet joint by expansion and seal welding.

– Commonly used for steam generation.

– Large-format equipment

Our Valuable Client Portfolio

Here is a brief list of clients who have trusted our expertise and quality in the development of heat exchangers:

Contact us

¡Contact us! We are ready to help you.