Environmental control equipment

Environmental control equipment

Marcando un paso crucial hacia un futuro más limpio y saludable

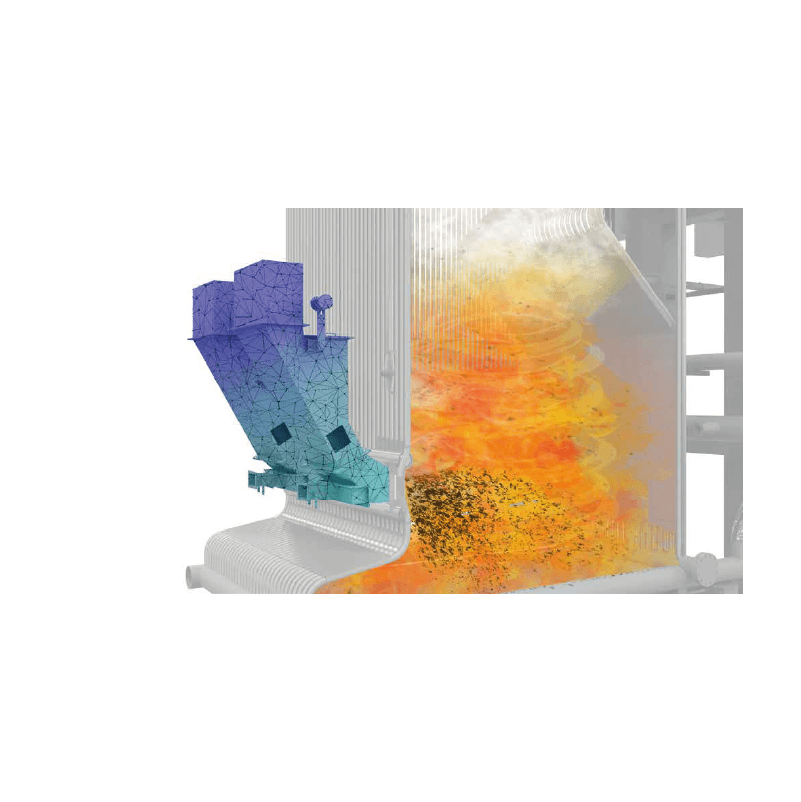

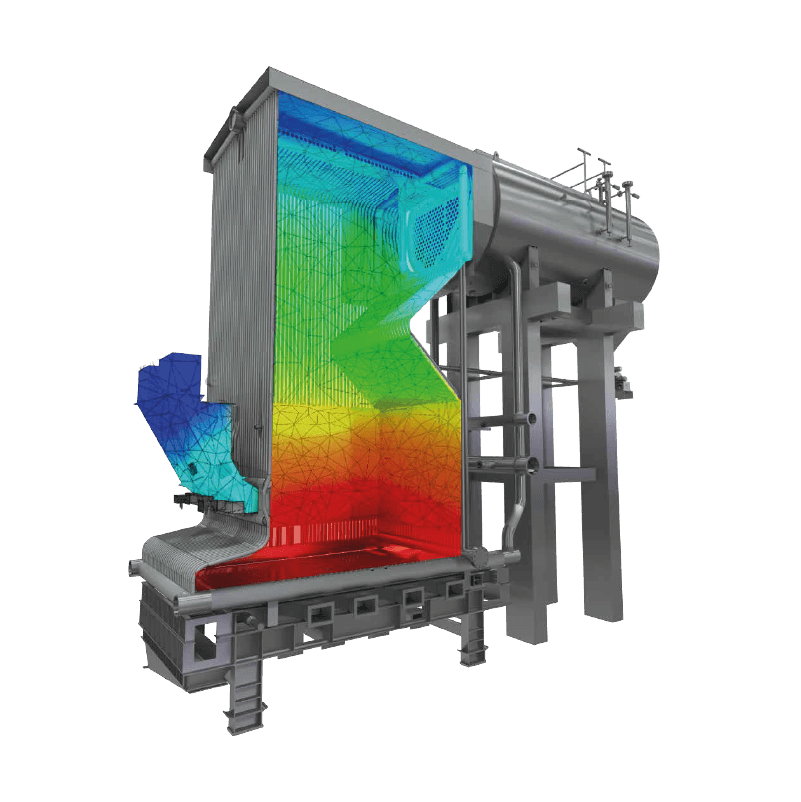

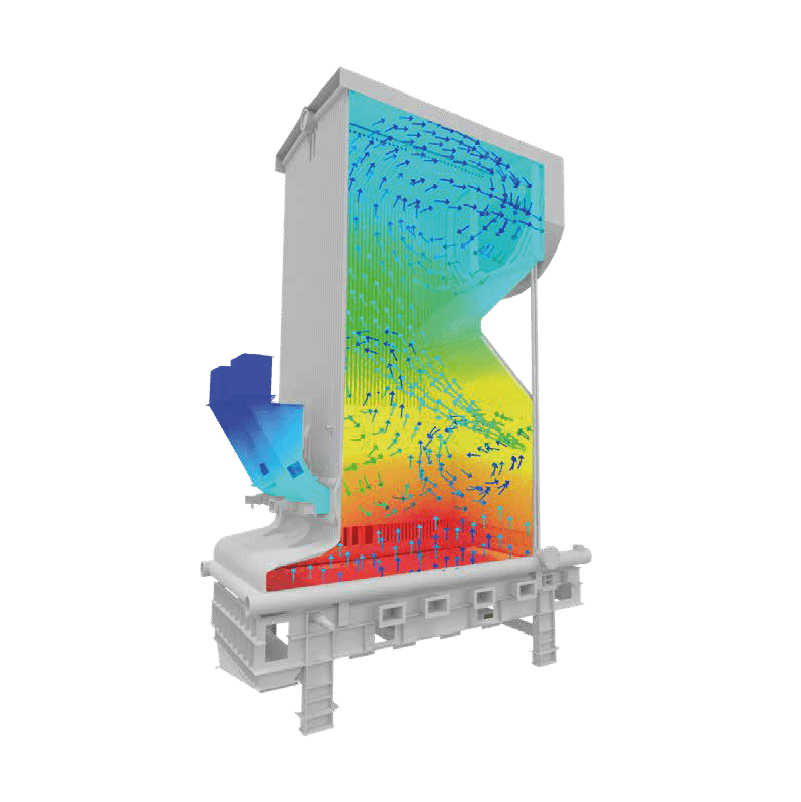

The transformation of raw materials and the use of fossil fuels or biomass generate a significant amount of particulate matter, which must be captured using specialized filtration equipment. These systems are designed specifically to capture particles of various sizes, withstand high combustion gas temperatures, and resist acidic characteristics, fully adapting to the specific needs of each industrial process.

- High-efficiency multi cyclones

- Pulse-jet filter bags

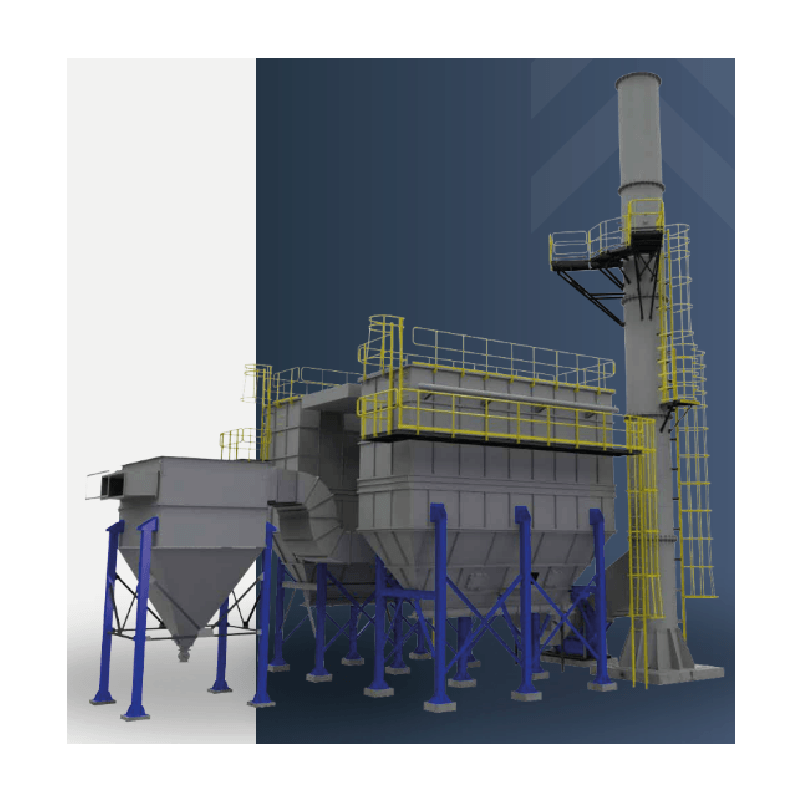

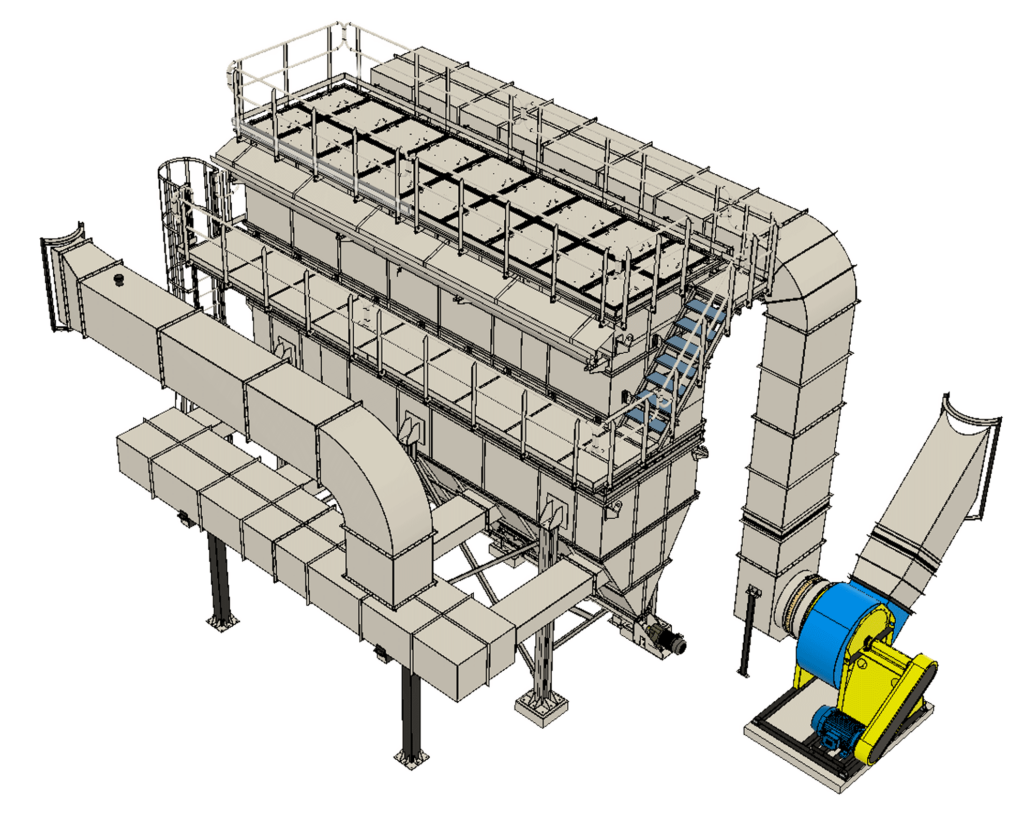

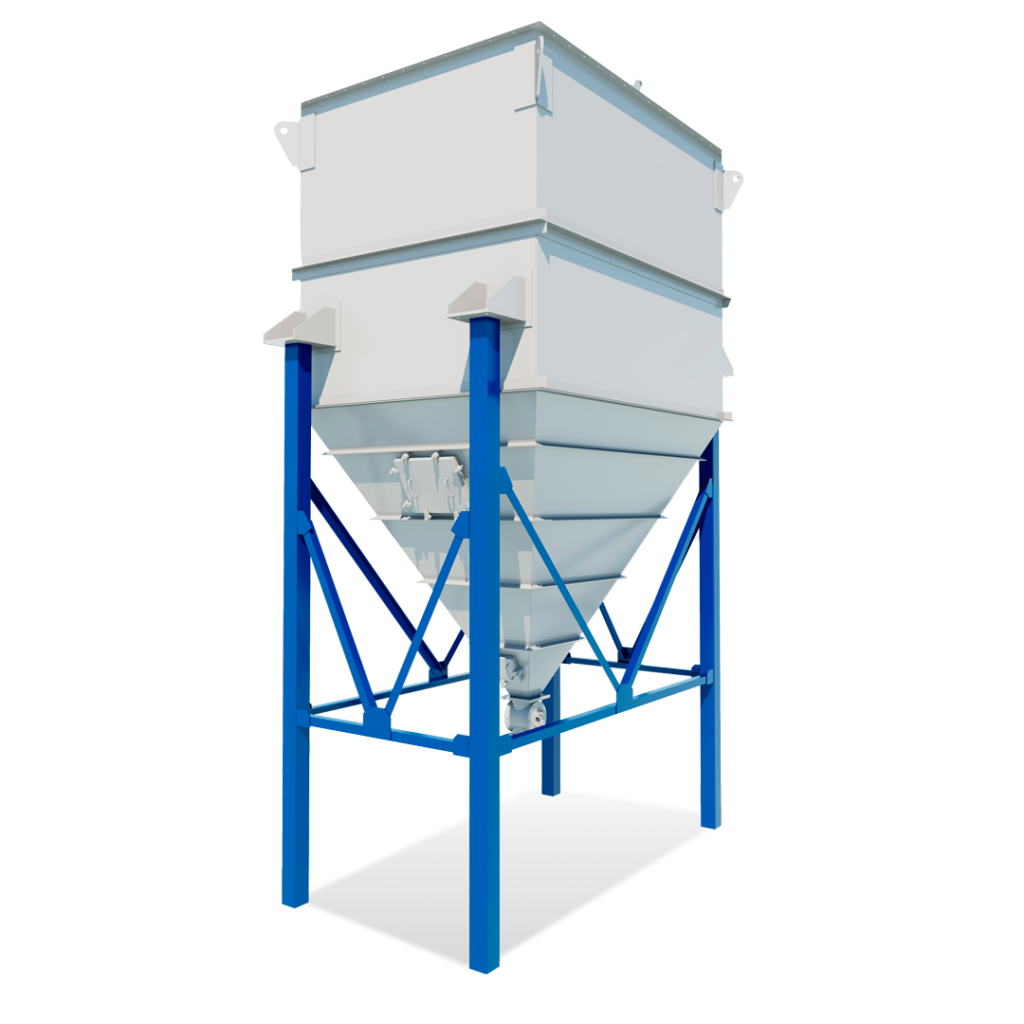

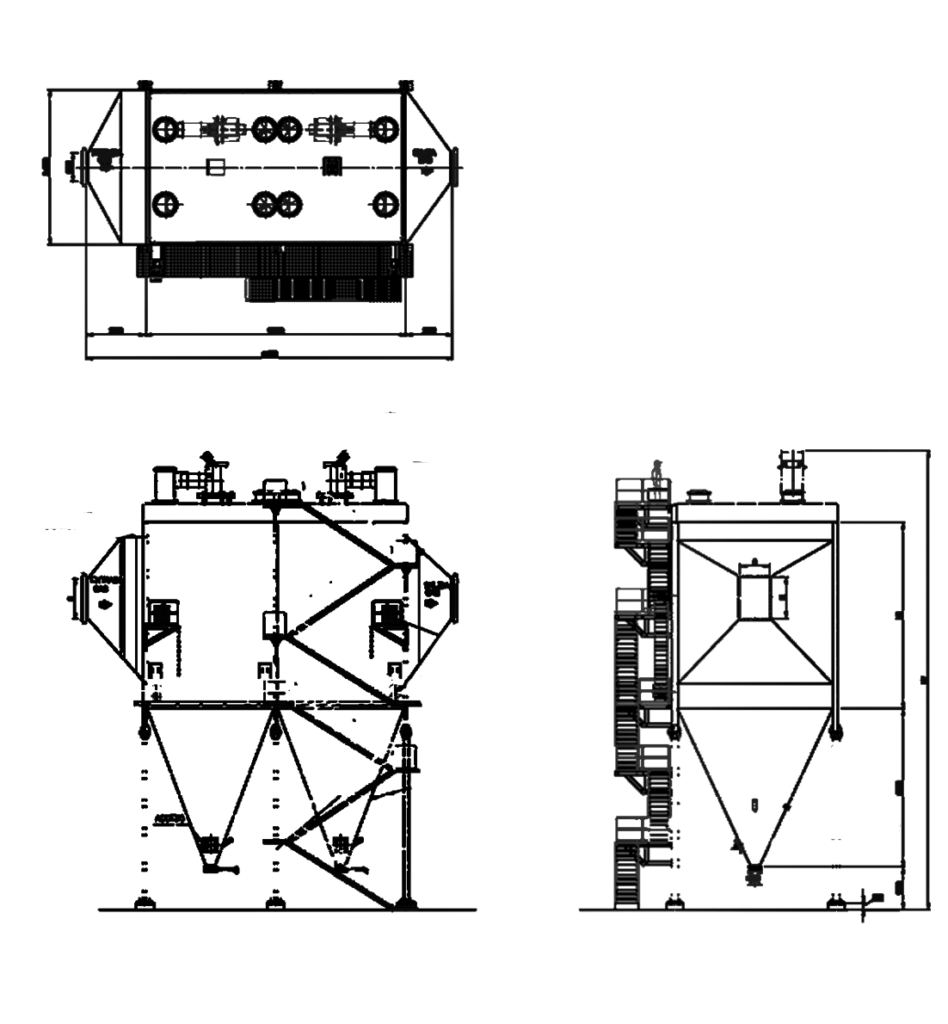

Baghouse filter

Our design incorporates filtering agents known as ‘Bags,’ made from various materials based on each client’s specific needs. Complemented by our advanced Pulse Jet automatic cleaning system, these filters are essential in numerous industrial sectors, including power generation, cement, metallurgy, chemical, and other processes involving boilers.

Key advantages

01. | Efficiencies up to 99%

02. | Ideal for Small Particle Sizes

03. | Continous Filtration

04. |Low Pressure Drop

05. |Low Maintenance

06. |Robust and Reliable Design

Pulse Jet Cleaning System

Hot gases mixed with particulate matter enter the equipment through the lower hopper and are filtered on the outer surface of the bags, which are supported by cages. Using modern pressure sensors, we automate the pulses of compressed air to clean the bags from the inside, dislodging the captured material and allowing the filtration process to continue.

Technical Specifications

| Operating temperature: | Up to 250°C |

| Efficiency | Up to 99,9% |

| Particle Size | >2,5 μm |

| Solids at Outlet | < 50 mg/Nm3 |

| Bag Material | Fibreglass / Polyester / PTFE |

| Gas Flow Rate | 5,000 a 200,000 m3/h |

Cyclones

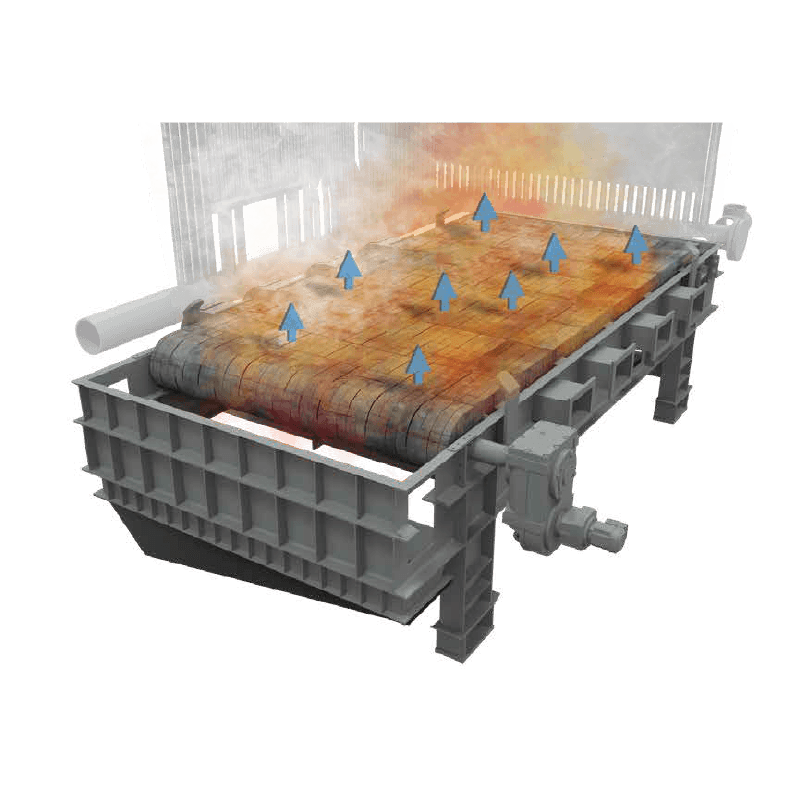

In a cyclone, the gases from combustion enter tangentially at the top of the equipment. As the diameter decreases in the cone section, the tangential flow velocity increases. This process, along with the change in flow direction, causes the particulate matter to adhere to the walls of the cyclone and fall by gravity. As a result, clean gases exit through the top of the equipment.

01. | No Moving Parts

02. | High Operating Temperatures

03. | Continous Filtration

04. | Versatility

04. | Low Cost

Technical Specifications

| Operating TemperatureUp | to 400°C |

| Efficiency | <95 % |

| Particle Size | >10 μm |

| Solids at Outlet | >200 mg/Nm3 |

| Manufacturing Material | A-36 / A-516 |

| Gas Flow Rate | 2,000 a 20,000 m3/h |

| Warranty | 2 Años |

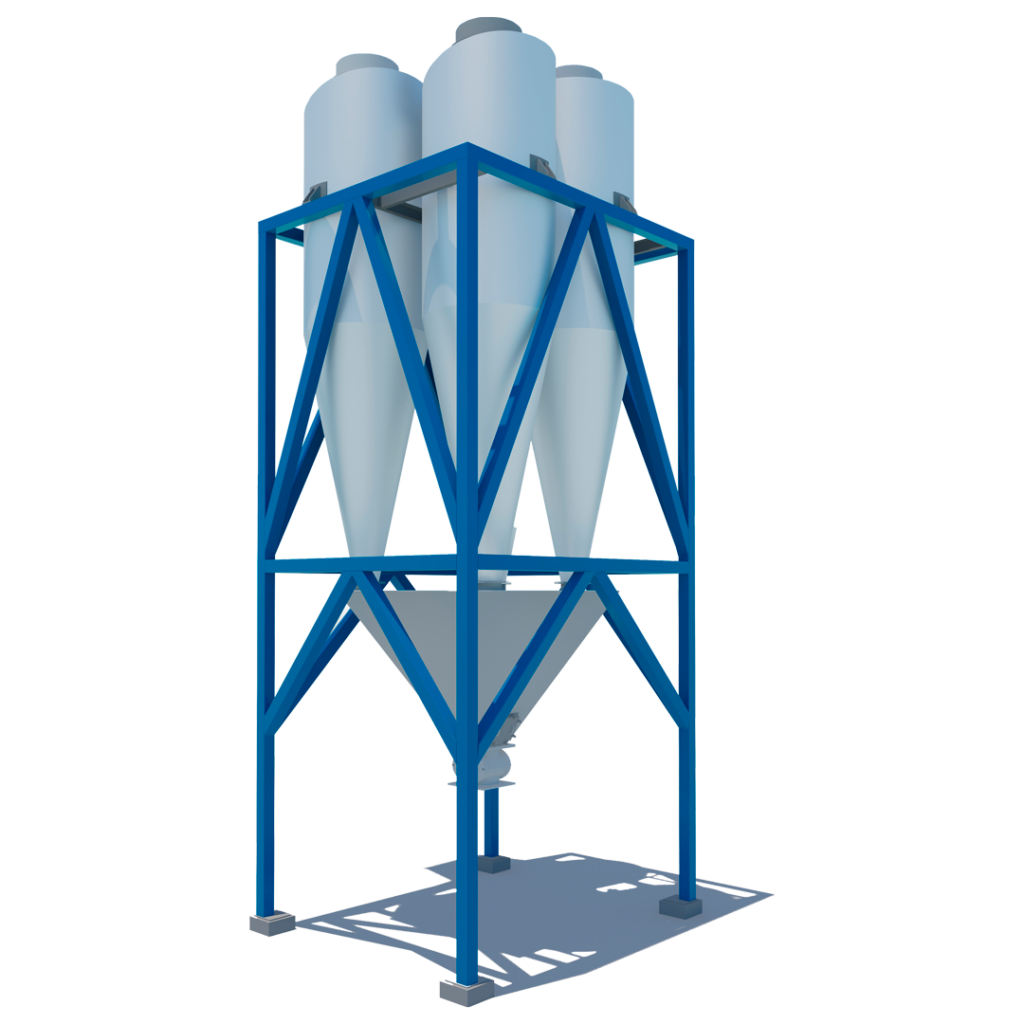

Multicyclone

01. | No Moving Parts

02. | High Operating Temperatures

03. | High Performance with Small Particles

04. | Versatility

A multicyclone employs a series of smaller, independently arranged cyclones. By reducing the size of the cyclone, the flow acceleration increases, resulting in greater efficiency in the collection of small particles. This advanced configuration allows for the treatment of air flow rates of practically any magnitude, thereby optimizing performance and process effectiveness.

Technical Specifications

| Operating Temperature | Up to 400°C |

| Efficiency | < 95% |

| Particle Size | >5 μm |

| Solids at Outlet | 50 a 200 mg/Nm3 |

| Manufacturing Material | A-36 / Gray Cast Iron |

| Gas Flow Rate | 10,000 a 100,000 m3/h |

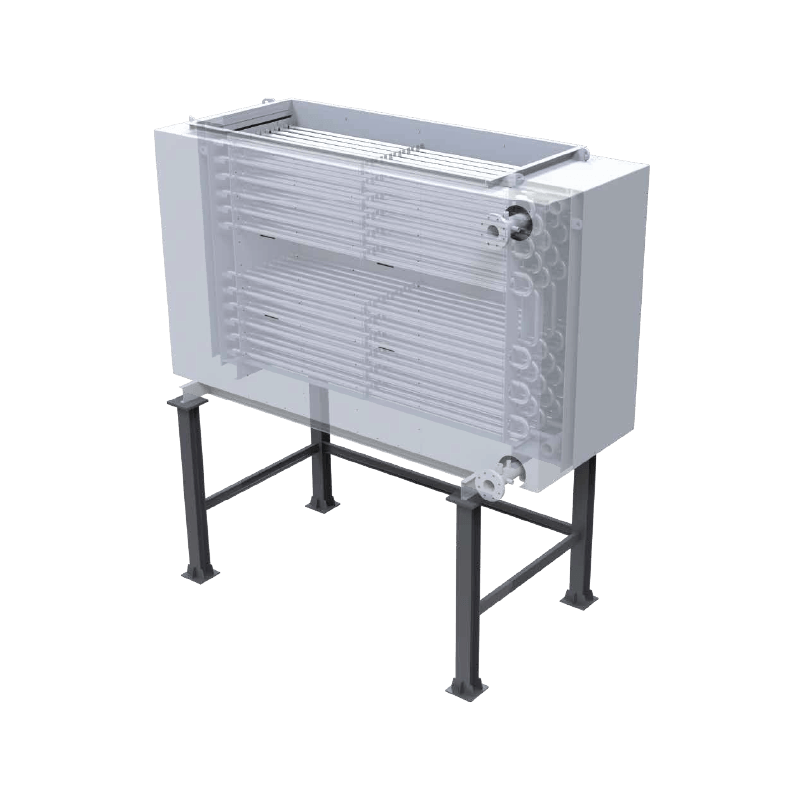

Electrostatic Precipitator

01. | High Filtration Efficiency

02. | Low Pressure Drop

03. | Handling of Large Flow Rates

04. |Handling of High Temperatures

05. | Flexibility

Electrostatic precipitators are highly efficient devices used in various industries for controlling pollutant emissions. They operate by applying an electric field that charges the suspended particles in the gas flow. These charged particles are then captured on collector plates with an opposite charge, where they accumulate and are periodically removed using automatic cleaning methods.

Technical Specifications

| Operating Temperatura: | 250 °C |

| Efficiency | > 90% |

| Particle Size | >0,1 μm |

| Solids at Outlet | < 50 mg/Nm3 |

| Manufacturing Material | A-36/A304 |

| Gas Flow Rate | 20,000 a 200,000 m3/hh |

Our Valuable Cliente Portfolio

Here is a brief list of clients who have trusted our expertise and quality in the development of Environmental Control Equipment:

Environmental Control Equipment with

High Quality

We specialize in the construction of environmental control equipment, designed and manufactured according to ISO standards. We meet the highest standards to provide reliable and durable products, contributing to environmental protection and ensuring efficient performance in every application.

Contact us

¡Contact us! We are ready to help you.