Control Panels

Industrial Process Control & Energy Management

Our experience developing automation systems allows us today to face complex projects with guaranteed success. Our knowledge in the areas of process, instrumentation, assemblies, and electrical panels enables us to develop safer and more reliable control logics, contemplating even the smallest detail in each application.

We design, program, and supply conventional control architectures or with special requirements, such as:

| High Risk Processes: SIL3 Architectures

| High availability processes: redundant architectures <<Hot Stanby.>>

| Highly adaptable processes in the operational stage: DCS architectures.

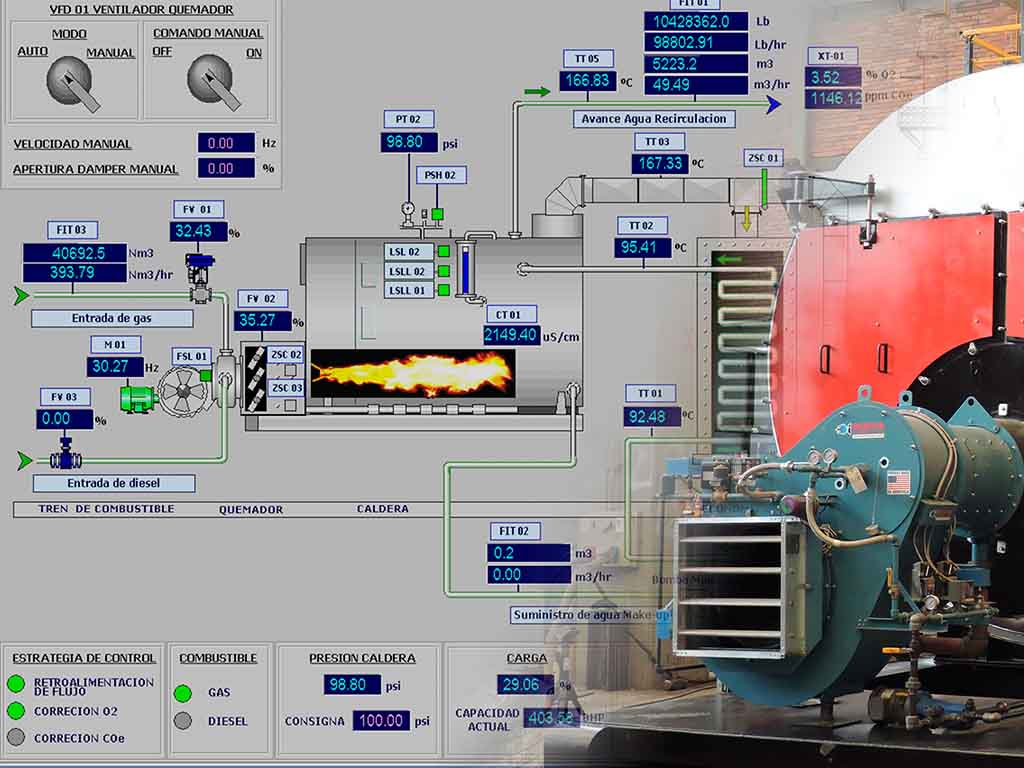

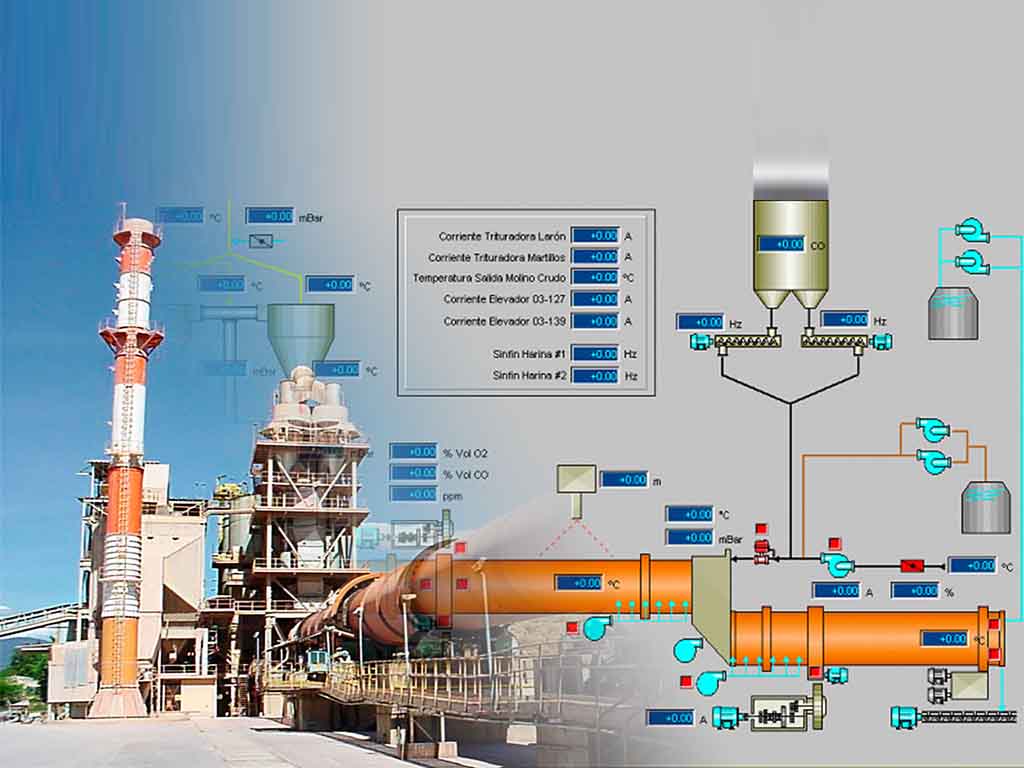

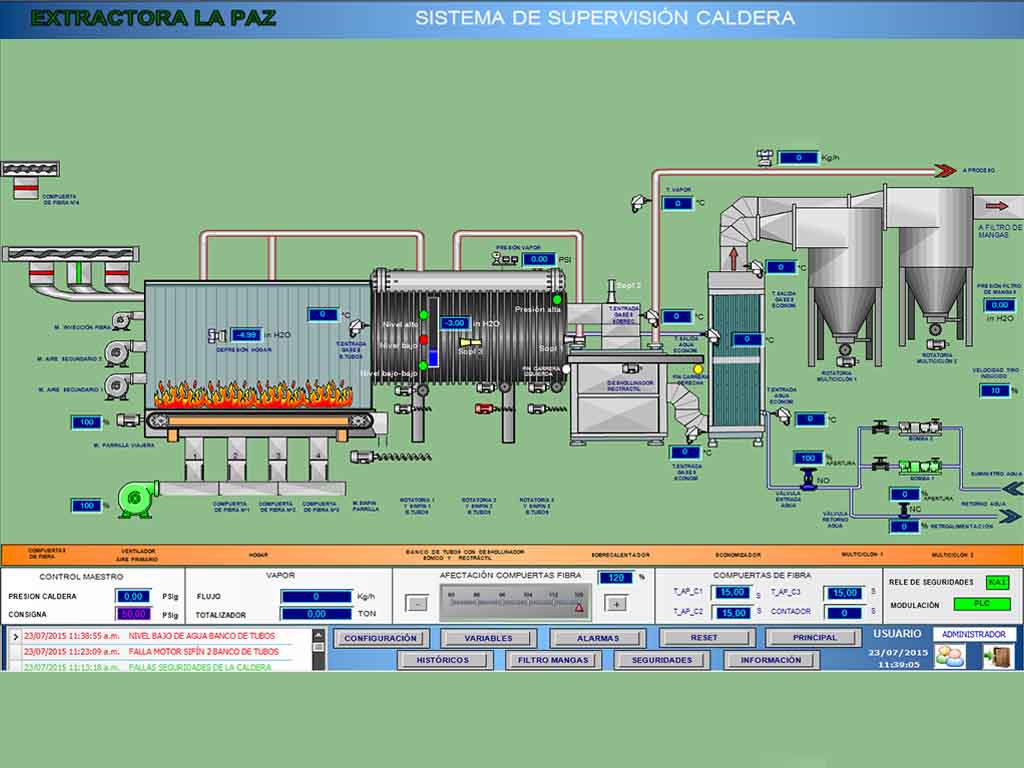

Supervision and process management

We develop supervision applications for each area of the production process:

| HMI (Human Machine Interface): For local operation and visualization of the process.

| SCADA (Supervisory Control And Data Acquisition): As a tool for analysis, parameterization, traceability, maintenance and process control.

| MES (Manufacturing Execution Systems): We automatically generate production efficiency or performance reports.

| ERP (Enterprise Resource Planning): Statistical reports for resource analysis and planning.

We include redundant server architectures, independent data management, and application servers, web clients for remote monitoring, or clients for viewing on mobile telephony.

Control of combustion and heat transfer processes

Being manufacturers with our own designs of boilers and equipment for various industries and having the experience of having automated hundreds of industrial processes assure us a detailed knowledge of the control, instrumentation, and supervision requirements in areas such as:

| Combustion heat generation: steam boilers, water heaters, thermal oil heaters, process gas heaters, fire heaters.

| Oil & Gas sector: raw water gas separators, heat exchangers, LACT metering units, fire heaters, boilers, KO drums, scrubbers, nutshell filters, pig launchers.

| Cement manufacturing and handling, material conveying, bottling, packaging, CIP and, in general, industrial processes in the mining, food, beverage and water segments.

Alliance Partner – Schneider Electric

Industrial System Integration

(Industrial System Integrator)

Contact us

¡Contact us! We are ready to help you.