Heat Recovery Boilers

Energy Efficiency

Optimize your industrial processes

Con Calderas Recuperadoras de Calor

Industries need to improve their production processes to be more efficient in the use of energy resources. Steam is one of the most important resources, used in sectors such as chemical manufacturing, power generation, and food processing.

Heat recovery boilers are the ideal solution for optimizing steam usage and reducing costs by utilizing waste heat from other industrial processes. This utilization not only improves energy efficiency but also contributes to environmental sustainability by reducing greenhouse gas emissions.

Recovery boilers consist of key modules such as evaporators and superheaters, which are essential for harnessing waste heat and generating energy. These components improve efficiency in industrial processes like refinery cracking and contribute to sustainable energy development.

Main Advantages

Energy Efficiency

They take advantage of waste heat, reducing energy consumption.

Emission Reduction

They reduce the carbon footprint, improving sustainability.

Rapid Return on Investment

Energy savings quickly offset costs.

Customized Solutions

Tailored to the specific needs of each industry.

Co-generation:

Industrial growth and energy consumption have increased significantly. To address these challenges, cogeneration systems have been designed to combine electricity generation and steam production. The implementation of microturbines coupled with conventional steam generation systems allows companies to meet their internal electricity demand while continuing to produce the steam necessary for production operations.

Initially reserved only for large industries, these systems now feature cutting-edge technologies that address specific needs for steam generation and efficient use of available space.

Success Stories

Explore some of our most notable projects and learn in detail how our solutions have made significant and positive impacts on our clients.

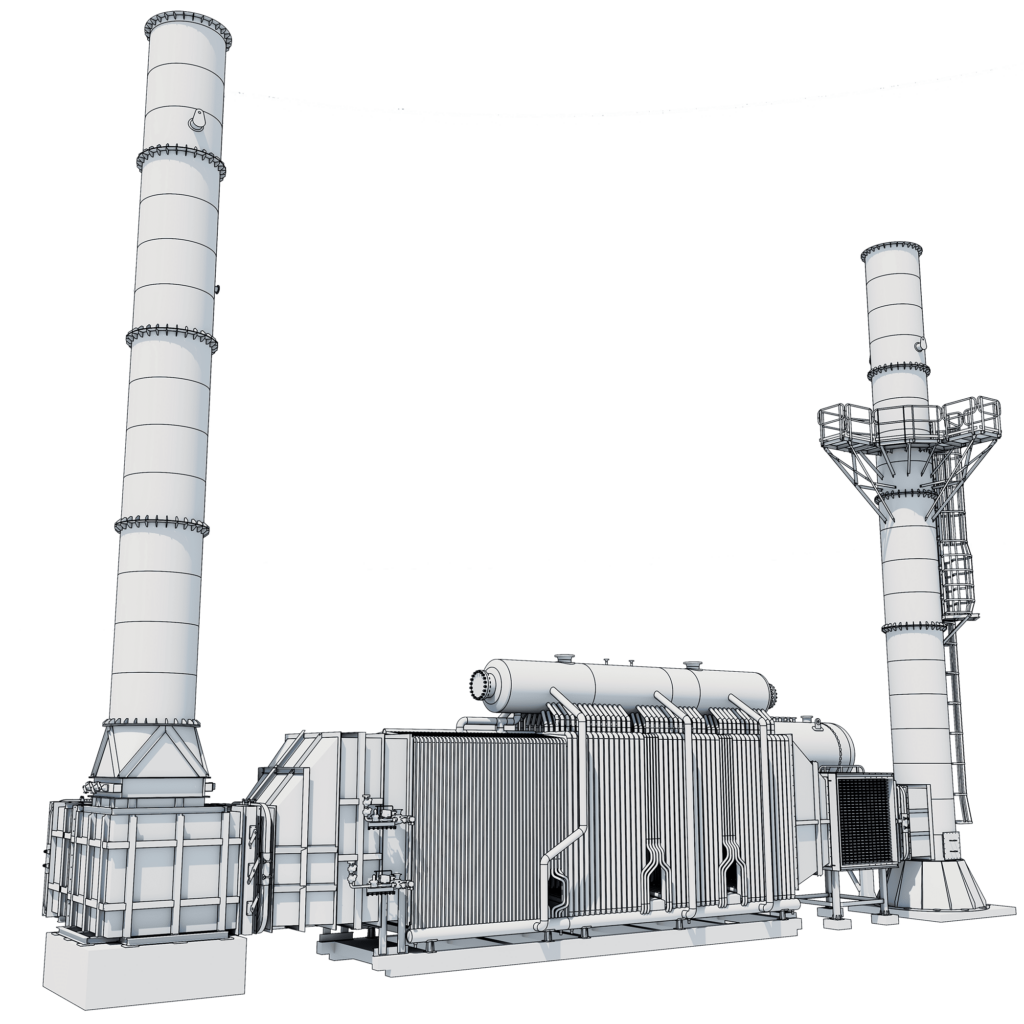

RECOVERY BOILER

Main components:

5 evaporator modules and 1 superheater.

Materials:

Pipe: SA-106 GR B, SA-312 TP 316, SA-335 P22.Tube: SA-192, SA-213 T22.

Capacity:

200 tons of piping.

Welds:

16,000 joints, inspected with non-destructive testing.

Tecnology:

High-definition plasma cutting with beveling arm.

Tests:

High pressure and non-destructive.

Manufacturing Capacity

At VR Ingeniería, we have highly skilled human capital and state-of-the-art infrastructure necessary to handle large-scale manufacturing processes. Our experience and dedication allow us to offer comprehensive solutions, ensuring the highest quality and efficiency in every project.

Heat Recovery Boilers with

High Quality

We are specialists in the development of **Heat Recovery Boilers**. All our boilers are designed and manufactured following the guidelines of the **ASME Section I** code and meet the highest standards, ensuring the most **reliable and durable** products on the market.

Our Valuable Client Portfolio

Here is a brief list of clients who have trusted our expertise and quality in the development of Heat Recovery Boilers.

Contact us

¡Contact us! We are ready to help you.