Electrical assemblies

Secure energy and reliable solutions

Electrical assemblies

With a department exclusively in charge of electrical assemblies, we guarantee the safe transport of electrical energy from the process connection point (medium or low voltage) to the final consumption elements.

With strict regulatory compliance, we carry out the design, execution of works and project management of industrial electrical installations.

We offer our expertise and experience in the design, supply of materials, assembly, testing and documentation phases. We focus on low and medium voltage industrial electrical installations, as well as in areas classified with risk of explosion.

Industrial electrical assemblies in low voltage

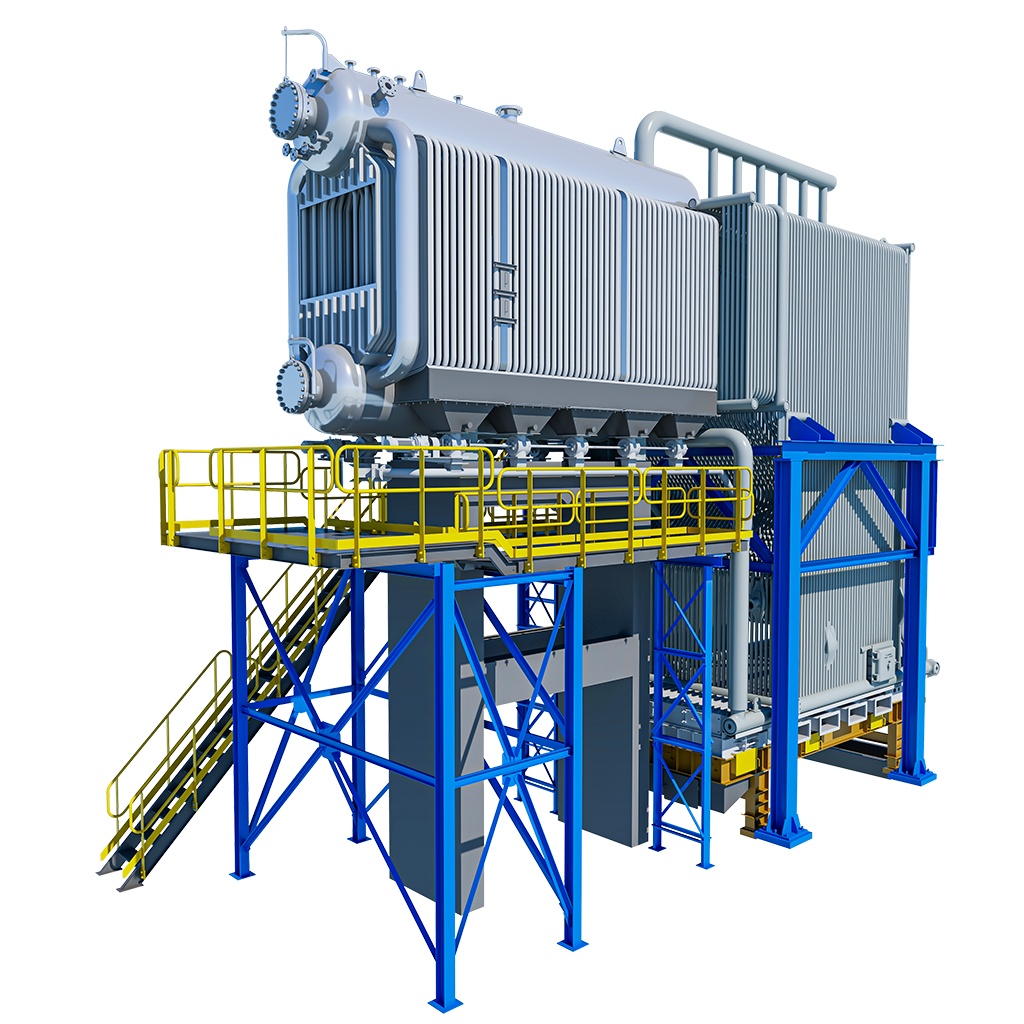

We develop industrial electrical assemblies for perimeter lighting or internal lighting, shielding, transformers, substations, environments classified with risk of explosion, and busbar systems. All products supplied have RETIE certification.

We provide support in the development of detailed engineering documentation, field management, testing, preparation of as-built documentation or auditing.

We have experience in hygienic electrical installations, with stainless steel piping, and in electrical installations in places with high temperatures such as boilers and furnaces.

Industrial electrical assemblies in low voltage

We develop industrial electrical assemblies for perimeter lighting or internal lighting, shielding, transformers, substations, environments classified with risk of explosion, and busbar systems. All products supplied are RETIE certified.

We provide support in the development of detailed engineering documentation, on-site supervision, testing, preparation of as-built documentation, or project oversight.

We have experience in hygienic electrical installations with stainless steel pipes, and in electrical installations in places with high temperature handling such as boilers and ovens.

Electrical assemblies in classified areas with explosion risk

We perform electrical assemblies ensuring that its components operate safely in areas classified with high risk of explosion, due to the presence of flammable gases, vapors or liquids, dusts, fibers or combustible particles, for the Oil & Gas sector or others that require it.

We develop only the assembly or integrate it with field wiring, FAT tests, SAT documentation and commissioning, depending on the needs of our customer.

All products supplied have both RETIE product certification and product certificate of compliance with international technical standards (UL, FM, CSA, Ex).

Electrical assemblies in areas classified with risk of explosion

We carry out electrical assemblies guaranteeing that its components operate safely in classified areas with high risk of explosion, due to the presence of gases, vapors or flammable liquids, dust, fibers or combustible particles, for the sector Oil & Gas or others that require it.

We develop the assembly alone or integrate it with field connections, FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) tests, documentation, and commissioning, depending on the needs of our client.

All products supplied have both a RETIE product certification and a product certificate of compliance with international technical standards (UL, FM, CSA, Ex).

Industrial electrical assemblies in medium voltage

We develop industrial electrical assemblies for perimeter lighting or internal lighting, shielding, transformers, substations, environments classified with risk of explosion, and busbar systems. All supplied products are RETIE certified. All products supplied have RETIE product certification.

We provide engineering services for the development of detailed engineering documentation, field management, testing, as-built documentation and auditing.

Industrial electrical assemblies in medium voltage

We develop industrial electrical assemblies for perimeter lighting or internal lighting, shielding, transformers, substations, environments classified with risk of explosion, and busbar systems. All supplied products are RETIE certified. We provide support in the development of detailed engineering documentation, field management, tests, preparation of as-built documentation or auditing.

We provide support in the development of detailed engineering documentation, field management, tests, preparation of “as built” documentation or auditing.

Busbar systems

We supply and assemble low voltage power distribution systems using copper or aluminum busbar ducts up to IP68 and 6300 A.

In places where rodents are a continuous problem for electrical cables, the blindobars are the optimal solution.

In places where style and ambiance play an important role, the blindobars provide a more aesthetic look to the electrical installation.

The blindobars have been tested in saline environments in coastal cities with excellent results.

Busbar systems

We supply and assemble low voltage power distribution systems using copper or aluminum bus ducts up to IP68 and 6300 A.

In places where rodents are a continuous problem for the electrical cables, bus bars are the optimal solution.

In places where style and environment play an important role, bus bars provide a more aesthetic aspect to the electrical installation.

Bus bars have been tested in saline environments in coastal cities with excellent results.

Contact us

¡Contact us! We are ready to help you.