Steam Generation Systems

Integrated and Specialized Solutions for the Steam Production Industry

Process Efficiency Optimization

In today’s dynamic industrial landscape, the ability to make accurate and timely decisions is crucial to maintaining a competitive edge. Simply incorporating the best equipment into our production systems is no longer enough. It is essential to integrate and interconnect these pieces of equipment so that they operate in a coordinated manner, functioning as an integrated system. This approach not only optimizes efficiency but also enhances overall performance.

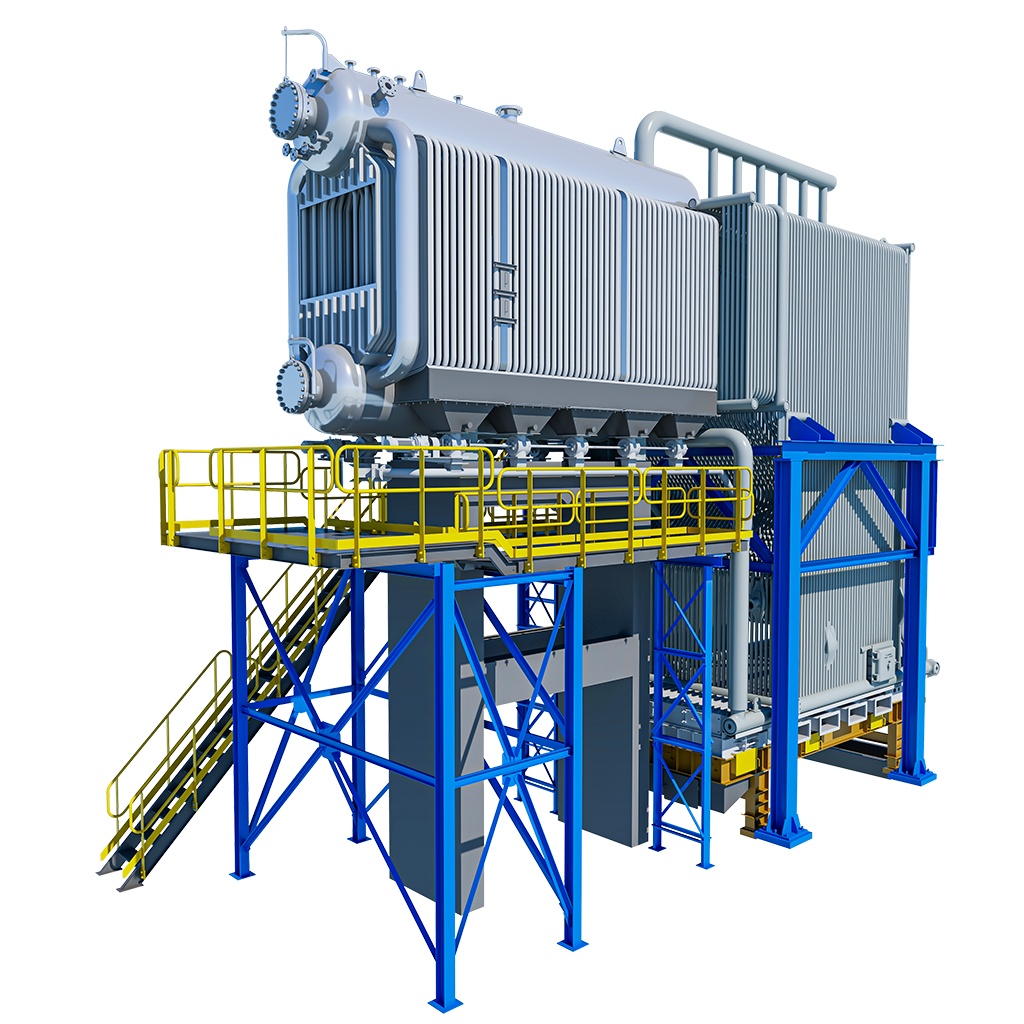

Steam Generation Plants

Our ability to integrate and connect various disciplines allows us to offer customized turnkey solutions tailored to the specific needs of each client. We focus on optimizing production outcomes in key areas such as supervision, combustion control, environmental control, maintenance, and energy efficiency. Additionally, we ensure regulatory compliance through constant support, guaranteeing that our manufacturing quality not only meets but exceeds even higher standards.

These solutions are designed to make the operation of boilers for steam production more practical and efficient in the petrochemical, food, and electric power generation sectors.

Supervision

The integration of HMI, SCADA, MES, and ERP systems provides an advanced solution for control, monitoring, analytics, and data management. It incorporates precise instrumentation to efficiently monitor and manage industrial processes, enabling centralized, real-time control and facilitating continuous supervision of multiple operational variables.

- Economizers

- Superheathers

- Condensate Management

- Steam Flow Optimization

Combustion Control

Combustion control with intelligent dosing and modulated burners represents a crucial innovation in industrial energy efficiency. By precisely adjusting the air percentage in combustion processes, a significant reduction in unburned fuel is achieved, optimizing performance and minimizing environmental impact.

- Smart Dosing.

- O₂ Percentage Control.

- Modulating Burners.

- Unburned Reduction.

- Fuel Consumption Reduction

Environmental Control

These advanced systems allow for the efficient capture of contaminant particles and gases, thereby ensuring compliance with rigorous environmental regulations.

- Bag Filters

- Desulfurizers

- Electrostatic Precipitator

- Emission Reduction

- Cyclones

Maintenance

These practices ensure that industrial systems operate optimally and safely, minimizing downtime and maximizing asset lifespan.

- Diagnosis

- Standardization of Routines

- Calibration

- Update

Energy Efficiency

The use of specialized equipment to optimize energy consumption represents a substantial reduction in operating costs and improves environmental sustainability.

Variable frequency adaptation for fan and pump motors with advanced control logic.

- Economizers

- Superheathers.

- Condensate Management.

- Steam Flow Optimization.

Success Stories

Legacy of the Rubiales Project

From Metapetroleum to becoming part of Ecopetrol as the Rubiales Field, this project has been an example of growth and transformation in Colombia’s energy sector.

Metapetroleum Boiler

5 Boilers: With a capacity of 60,000 lb/hr.

Fuel: Crude Oil – Diesel

Fuel consumption: 3,863 lb/h.

Capacity: 60,000 lb/h with feedwater at 105°C.

Maximum operating pressure: 170 psi.

Design pressure: 250 psi.

Maximum steam temperature: 375 ºF.

Fuel supply pressure to the burner: 30–35 psi.

Efficiency: 86.8%

Cervalle

-Fuel: Coal and natural gas.

-Number of boilers: 3 boilers of 1,100 BHP.

-Capacity: 17,000 kg/h of saturated dry steam with feedwater at 110°C.

-Maximum operating pressure: 180 psig.

-Efficiency: 87.4% with coal and 93% with natural gas.

This project includes three combined boilers equipped with a traveling grate, designed to operate with coal as the primary fuel and natural gas as an alternative. The system ensures high efficiency and precise combustion control, meeting the highest quality and safety standards in accordance with the ASME code.

Recognition from Bavaria

Cervecería del Valle: Bavaria has honored us with its prestigious awards, recognizing our efforts and contribution to the industry.

Our Valuable Client Portfolio

Here is a brief list of clients who have trusted our experience and quality in the development of steam generation systems.

Steam Generation Systems with

High Quality

We specialize in the construction of steam generation systems. All our steam generators are designed and manufactured in accordance with the ASME Code Section I and meet the highest standards, resulting in the most reliable and durable products on the market.

Contact us

¡Contact us! We are ready to help you.