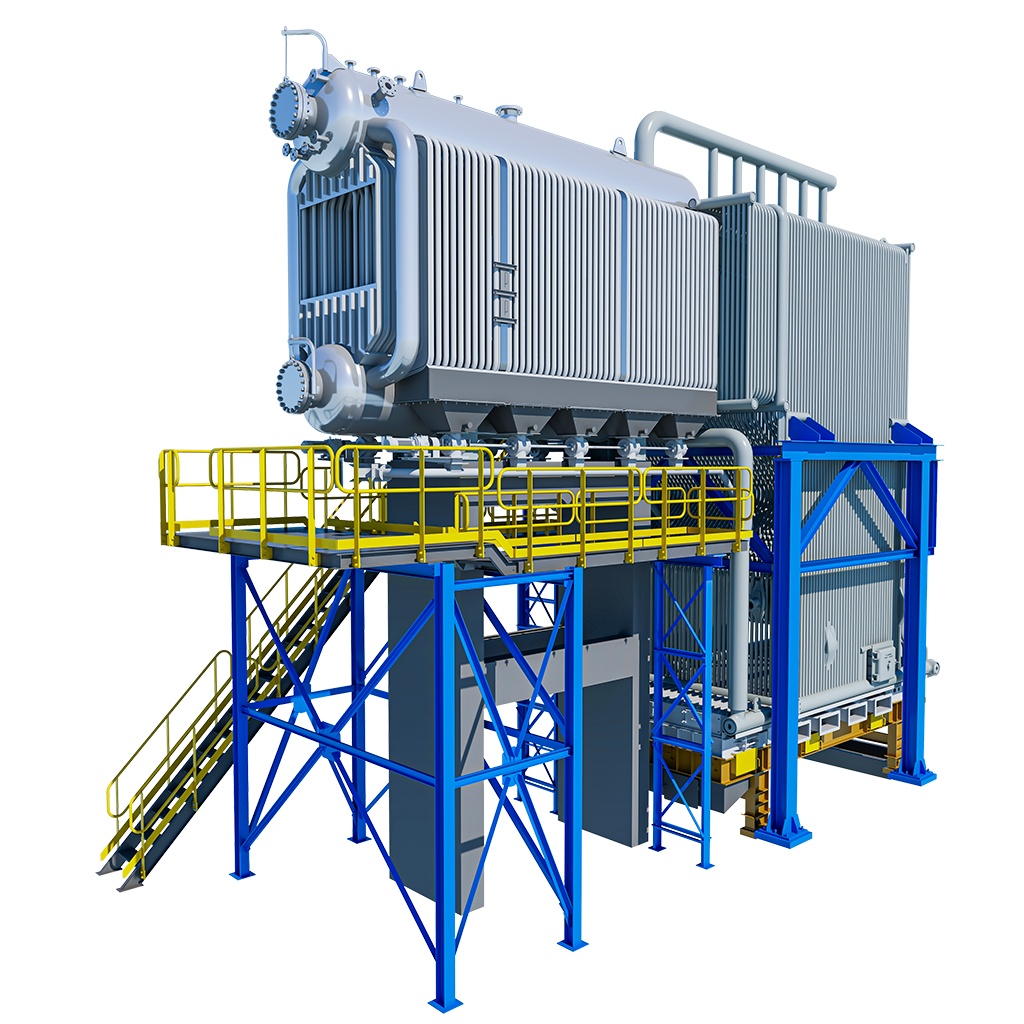

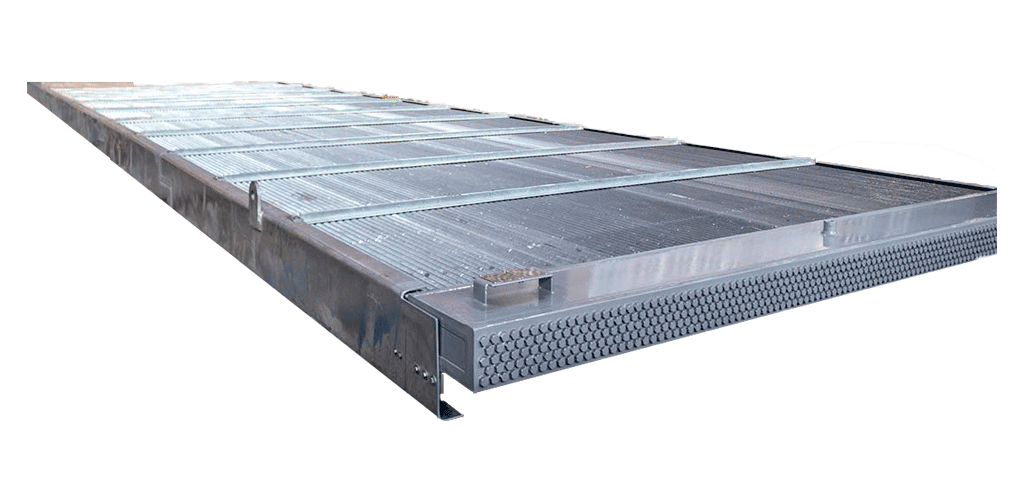

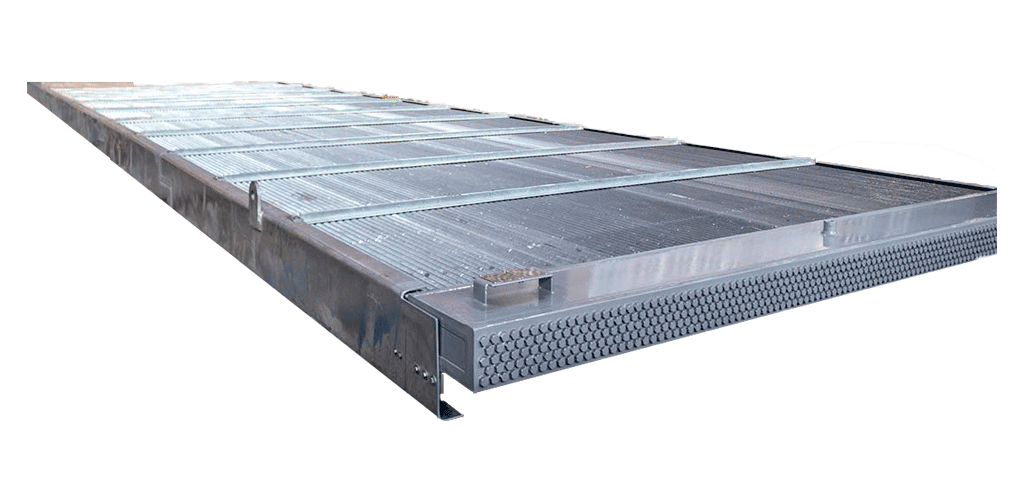

Industrial Air coolers

Solutions for process fluid cooling.

We manufacture high-performance industrial air coolers.

Ofrecemos aeroenfriadores para la condensación o enfriamiento de fluidos de proceso utilizando una corriente de aire, cumpliendo con las normativas:

ASME – Sección VIII, Div 1, Estampe “U”

API 661 – AIR-Cooled Heat Exchangers.

We use finned tubes in G-type, L-type, or extruded aluminum.

The air coolers can be supplied as a package unit with structure, platform, instrumentation, control, and supervision, or they can be supplied separately.

Manufacturing Capacity

Nearly of 40 years of experience

Nearly 40 years in the industry guarantee our expertise and knowledge in the production of industrial air coolers.

High Quality Standards

Producción con los más altos estándares de calidad para asegurar la fiabilidad y durabilidad de nuestros productos.

Technology

We combine technology and technical expertise with efficient processes to ensure reliability in every product we manufacture.

Extensive Production Capacity

We are equipped with the best technology for precision part manufacturing, ensuring exceptional results.

We design custom equipment

We design custom air coolers to meet the specific needs of each client. Our team uses specialized software to perform mechanical, thermal, and hydraulic calculations, thus optimizing the performance, energy efficiency, and durability of our cooling systems.

We adhere to the most demanding industry standards and align our processes with international quality and safety standards. This commitment allows us to build trust with our clients and contribute to a more sustainable future.

Energy Efficiency:

We design our equipment to maximize heat transfer, which can result in more efficient energy use. This can reduce operating costs and greenhouse gas emissions.

Customization

We have the capability to design and manufacture custom heat exchangers to meet the specific needs of each customer. This can result in products that are better adapted to the plant's operations and can improve its performance.

Versatility

We design for a wide range of temperatures and pressures, making them suitable for various applications.

Quality

All our heat exchangers are subjected to rigorous testing and quality assurance tests to guarantee their performance and durability. Our commitment to quality is unwavering.

Durability

Thanks to precise material selection and a detailed manufacturing process, our heat exchangers are more durable and require less maintenance. This can reduce long-term costs and minimize plant downtime.

Regulatory Compliance

All our products comply with industry regulations and standards, such as the ASME code. This ensures the safety and efficiency of the heat exchangers.

Technological Innovation

We invest in research, innovation, and development to provide heat exchangers that utilize the latest technologies and materials available, aiming for improved performance and greater energy efficiency.

We design our equipment to maximize heat transfer, which can result in more efficient energy use. This can reduce operating costs and greenhouse gas emissions.

We have the capability to design and manufacture custom heat exchangers to meet the specific needs of each customer. This can result in products that are better adapted to the plant’s operations and can improve its performance.

We design for a wide range of temperatures and pressures, making them suitable for various applications.

All our heat exchangers are subjected to rigorous testing and quality assurance tests to guarantee their performance and durability. Our commitment to quality is unwavering.

Thanks to precise material selection and a detailed manufacturing process, our heat exchangers are more durable and require less maintenance. This can reduce long-term costs and minimize plant downtime.

All our products comply with industry regulations and standards, such as the ASME code. This ensures the safety and efficiency of the heat exchangers.

We invest in research, innovation, and development to provide heat exchangers that utilize the latest technologies and materials available, aiming for improved performance and greater energy efficiency.

Features

| MATERIALS |

|---|

|

| Types of fins |

|---|

|

| Features |

|---|

|

Manufacturing Processes

We are leaders in the manufacture of air coolers, implementing production processes that guarantee energy efficiency and quality in each system. Our air coolers are designed to optimize resources and minimize environmental impact.

We are committed to excellence in every phase of production, ensuring that each step, from design to delivery, contributes to exceptional performance and reliable operation.

We use advanced welding techniques to ensure the integrity of our air coolers. Our trained and certified welders deliver joints that withstand the high pressures and temperatures typical of the operating conditions these units are subjected to.

Our precision machining processes allow us to manufacture components with tight tolerances, ensuring a perfect fit and optimal performance of our air coolers.

All our air coolers undergo rigorous testing to ensure their performance and durability. This includes pressure tests to verify the strength of materials and welds and leak tests to confirm the efficiency of the joints.

Success Stories

Explore some of our most notable projects and learn in detail how our solutions have made significant and positive impacts on our clients.

SUPPLY OF 12 AIR COOLERS FOR SERVICE WITH H₂S, H₂, AND H₂O

Stamping

PWHT in accordance with ASME Section VIII Division 1, API-661, NACE MR0103, and NACE RP-0472.

Construction materials

Pipes: SA-179 fully killed

Fins: Aluminum / Type: Embedded 0.4 mm Headers: SA-516 GR 70 + H₂S

Service conditions

Working pressure: 40 psig

Maximum operating temperature: 300 °F

Number of tubes: 288

SUPPLY OF ONE AIR COOLER

Overall dimensions

Total length: 15,490 mm

Total width: 4,323 mm

Total weight: 13,470 kg

Heat transfer: 5,200,000 BTU/h

Number of passes / rows: 1 pass / 5 rows

Number of tubes: 560

Working pressure: 10 psig

Maximum operating temperature: 210 °F

Service type: Process gas

Installation: Connection type: NPS 10 CLASS 150 ASME B16.5 RF flanges.

SUPPLY OF TWO TUBE BUNDLES AND ONE AIR COOLER

Overall dimensions of the air cooler

Total length: 19,490 mm

Total width: 2,750 mm

Total weight: 8,845 kg

Thermal capacity

Heat transfer: 11,117,770 BTU/h

Number of passes / rows: 1 pass / 4 rows

Number of tubes: 262

Service conditions

Working pressure: 18 psig

Maximum operating temperature: 250 °F

Service type: Process gas

Installation

Connection type: NPS 10 CLASS 150 ASME B16.5 RF flanges.

SUPPLY OF TWO BUNDLES FOR AIR COOLER

Tubes: SA-179.

Fins: ALUMINUM 1060 H14, Type L, 0.39 mm.

Header: SA-516 GR 70.

Tube diameter: 1 inch, minimum 14 BWG.

Tube bundle length: 38 feet and 1/4 inch.

Overall dimensions of the air cooler: Total length: 11,820 mm.

Total width: 3,590 mm

Total weight: 11,194 kg.

Heat transfer: 17,477,400 BTU/h.

Number of tubes: 363.

Working pressure: 52 psig.

Maximum operating temperature: 200 °F.

Service type: Lean amine.

Connection type: NPS 3 CLASS 150 ASME B16.5 RF flanges.

Our Valuable Client Portfolio

Here is a brief list of customers who have relied on our experience and quality in the development of air coolers:

Contact us

¡Contact us! We are ready to help you.