Two-Phase Test Separator for the Oil & Gas Sector

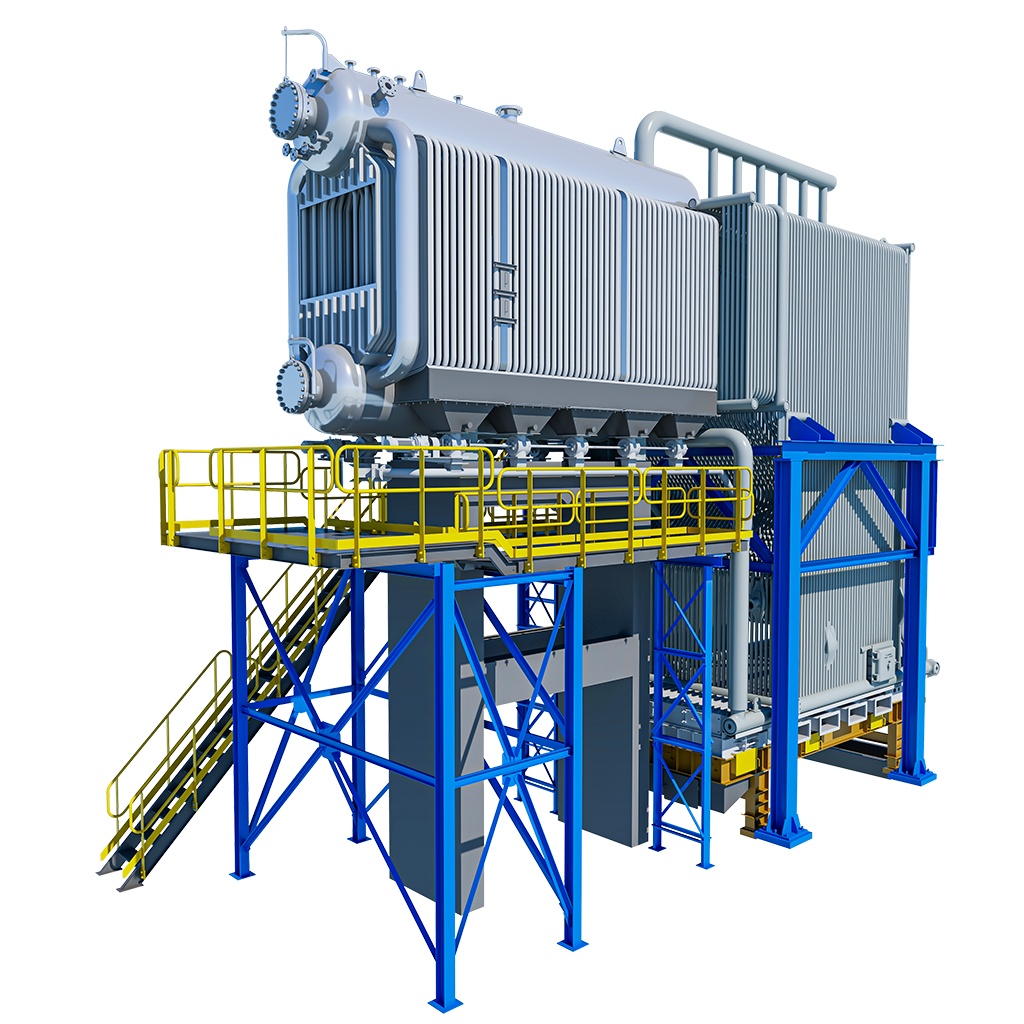

At VR Ingeniería, we remain committed to developing advanced technological solutions for the Oil & Gas sector. Today, we introduce one of our latest projects: the Two-Phase Test Separator, designed and manufactured for installation at the Oripaya gas plant, located in the municipality of San José de Cúcuta. This equipment plays a key role in the **operation and production control** of gas and oil.

What is a Two-Phase Separator?

A two-phase separator is a specialized equipment whose main function is the separation of gas and liquid. separation of gas and liquid (usually oil). In addition to its use in proper reservoir management, it is essential for diagnosing well problems and evaluating individual well production. This type of separator is used to improve efficiency and reliability in the operation of wells, ensuring proper management of energy resources.

Design and Manufacturing According to International Standards

This particular separator was designed and manufactured under the highest quality standards, following the ASME Section VIII Division 2 design codes, which establish strict guidelines for high-pressure equipment. This not only enhances the equipment’s performance but also ensures its safe operation.

Our two-phase separator has a design pressure of 2000 PSI and has been manufactured with strict specifications, making it ideal for operating in demanding environments within the Oil & Gas sector. Additionally, it complies with Resolution 41251 of the Ministry of Mines and Energy, ensuring the accurate measurement of hydrocarbons for the settlement of royalties and economic compensations.

Two-Phase Separator Features

One of the most outstanding features of this equipment is its “plug and play” design. This means it arrives fully ready to be installed and put into operation at the production well. The equipment includes:

Mechanical and Structural Components

Robust design integrating all necessary components to ensure optimal and efficient operation under any working conditions.

Instrumentation and Automatic Control:

The separator is fully automated, featuring optimization strategies and reliable control and instrumentation equipment, always ensuring safety.

In addition, the separator integrates a PLC (Programmable Logic Controller) that monitors all processes through an HMI (Human Machine Interface), from which pressures and levels are controlled. control pressures and levels in real time. levels of the equipment in real time. This allows a safe and efficient operation, ensuring compliance with the highest industry standards.

Contact us

For more information on this separator and other products and services we offer. and other products and services we offer.

We continue to transform, connect and integrate technologies for a more sustainable and efficient future.

A Key Project for the Industry

Transformamos ideas en proyectos exitosos.

contribuyendo al desarrollo del sector Oil & Gas

With this two-phase separator, at VR Ingeniería we continue to strengthen our leadership in the metalworking industry and in providing solutions for the energy sector. Each of our projects is backed by our commitment to our clients and a strict adherence to international regulations.