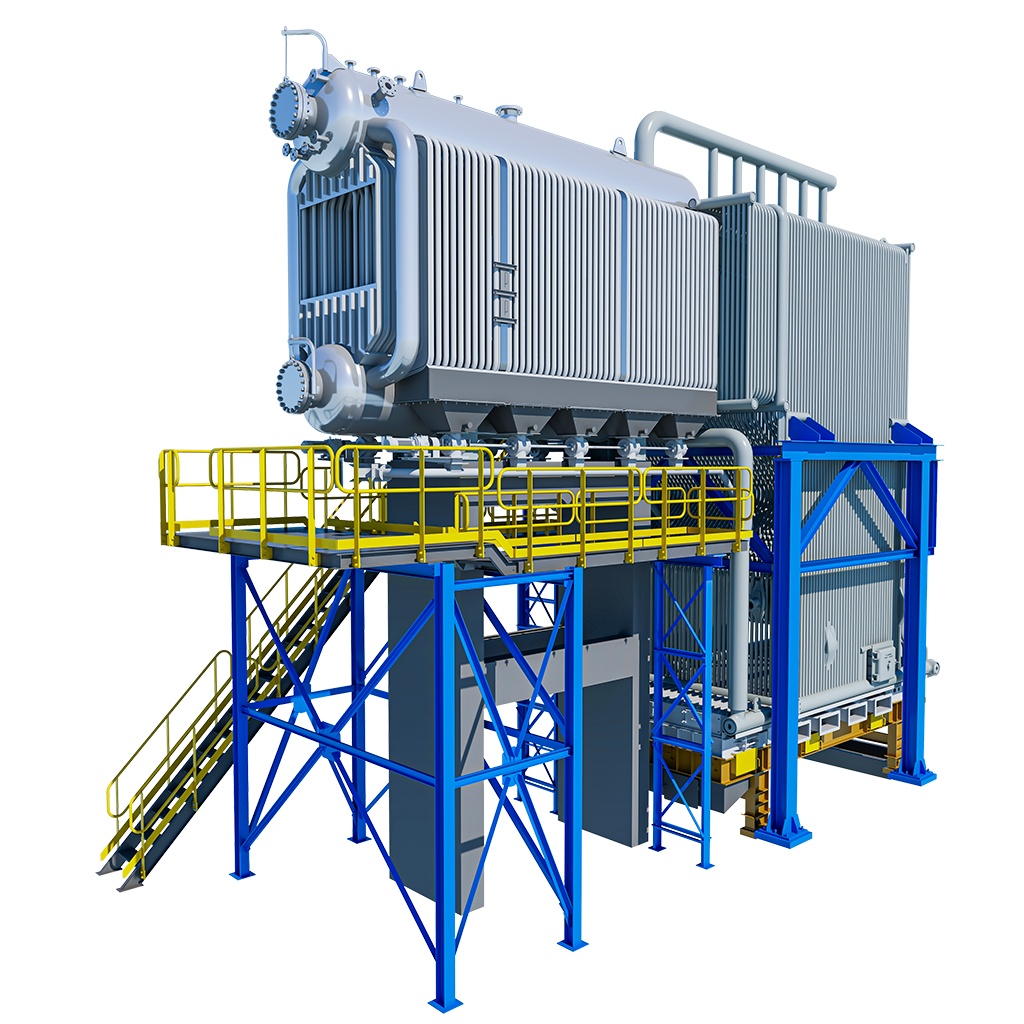

Refractory Systems for Boilers

Refractories for Boilers

Refractories protect boilers from extreme heat, improve efficiency, and extend their service life. At VR Ingeniería, we have optimized our refractory systems for boilers, achieving greater thermal efficiency and lower fuel consumption, ensuring safe and reliable performance.

Greater Energy Efficiency

They help reduce heat loss, optimizing equipment performance and improving energy consumption

High-Temperature Protection

They reduce the need for repairs and lower fuel consumption.

Corrosion and Abrasion Resistance.

Designed to withstand thermal changes and corrosion, reducing wear and maintenance.

Reduction of Operating Costs.

They reduce the need for repairs and lower fuel consumption.

Specific Applications

Fire-Tube Boilers

- Refractory Blocks for Burners and Pre-cast Shapes (including drying).

- Refractories for Doors, Manholes, and Inspection Openings.

- Internal Deflectors for Gas Flow Direction Change.

Water-Tube Boilers

- Design and Installation of Furnace and Chimney Refractories.

- Side Seals for Traveling Grate and Boiler Walls.

- Refractory Blocks for Burners and Pre-cast Shapes (including drying).

Manufacturing and Quality Control.

- Equipment for the Preparation and Vibration of Refractory Concrete.

- Support of API 936 Inspectors throughout the Design and Installation Process.

- Compliance with National and International Quality Standards.

Our Valuable Cliente Portfolio

Here is a brief list of clients who have trusted our expertise and quality in boiler development:

Contact us

¡Contact us! We are ready to help you.

Refractories for Boilers

Refractories protect boilers from extreme heat, improve efficiency, and extend their service life. At VR Ingeniería, we have optimized our refractory systems for boilers, achieving greater thermal efficiency and lower fuel consumption, ensuring safe and reliable performance.

Greater Energy Efficiency

They help reduce heat loss, optimizing equipment performance and improving energy consumption

Corrosion and Abrasion Resistance.

Designed to withstand thermal changes and corrosion, reducing wear and maintenance.

High-Temperature Protection

They reduce the need for repairs and lower fuel consumption.

Reduction of Operating Costs.

They reduce the need for repairs and lower fuel consumption.

Specific Applications

Fire-Tube Boilers

- Refractory Blocks for Burners and Pre-cast Shapes (including drying).

- Refractories for Doors, Manholes, and Inspection Openings.

- Internal Deflectors for Gas Flow Direction Change.

Water-Tube Boilers

- Design and Installation of Furnace and Chimney Refractories.

- Side Seals for Traveling Grate and Boiler Walls.

- Refractory Blocks for Burners and Pre-cast Shapes (including drying).

Manufacturing and Quality Control.

- Equipment for the Preparation and Vibration of Refractory Concrete.

- Support of API 936 Inspectors throughout the Design and Installation Process.

- Compliance with National and International Quality Standards.

Our Valuable Cliente Portfolio

Here is a brief list of clients who have trusted our expertise and quality in boiler development:

Contact us

¡Contact us! We are ready to help you.