Biomass Boiler – Ecuador

VR Ingeniería, renowned for its excellence in manufacturing industrial equipment, has developed a high-quality Biomass Boiler that meets the strict guidelines of the ASME, Section 1 code. This boiler has been dispatched to our client in Ecuador and stands out for its advanced Energy Optimization System.

Cliente: Energy Palma

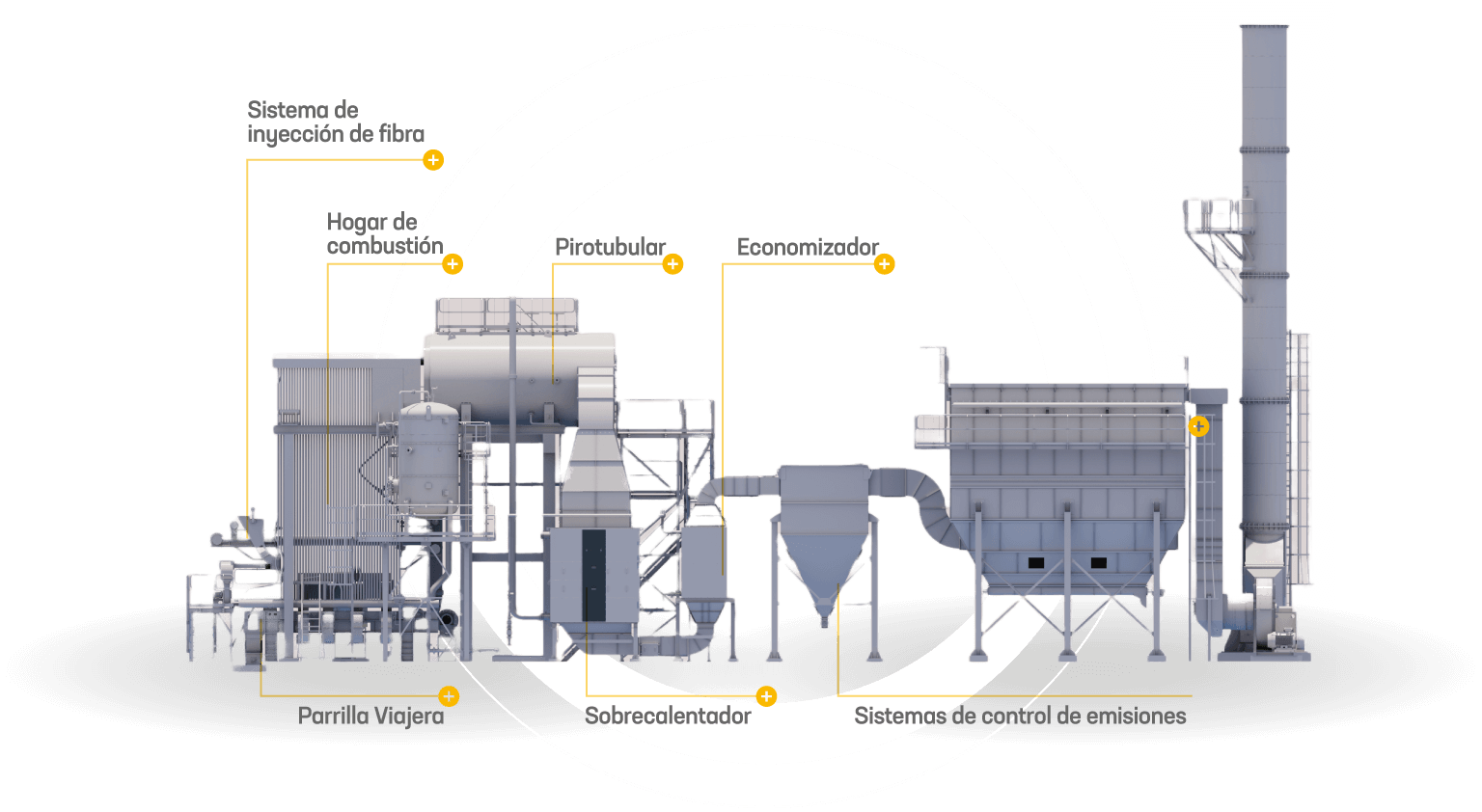

Products: Combined type boiler with water tube furnace, single-pass fire tube heat recovery, non-radiant superheater, and economizer. Equipped with a traveling grate, soot blower, and “AIR SWEPT DISTRIBUTOR” fuel feed system.

Dimensions: 6m x 4m x 1,5m

Capacity: 22,500 kg/hr of steam @ 22 bars superheated to 260°C with feedwater at 105°C

Standard: ASME R, ASME R, ASME U2, NBBI R, NBBI NB, ISO 9001:2015, ISO 14001:2015, ISO 45001:2018

Sector: Biomass

City: San Lorenzo, Ecuador

Energy optimization system